You’ll need five essential polishing tools to achieve professional jewelry finishes: Dremel or pendant motors for versatile polishing and texturing, rubber burrs in medium and extra-fine grits for surface smoothing, emery paper and sanding sticks in various grits for foundational finishing, calico and leather mop heads for buffing different metals, and specialized polishing compounds with finishing cloths for final luster. These cost-effective tools streamline your workflow while building diverse skills simultaneously, and mastering their specific applications will transform your jewelry-making results.

Dremel and Pendant Motors for Versatile Polishing

When you’re starting your jewelry-making journey, Dremel and pendant motors offer an affordable gateway into professional-level polishing without requiring expensive bench equipment.

These versatile polishing tools let you experiment across multiple techniques including engraving and texturing, making them perfect for developing diverse skills simultaneously.

Multi-technique polishing tools enable simultaneous skill development in engraving, texturing, and finishing for comprehensive jewelry-making mastery.

You’ll find rubber burrs particularly effective when paired with your Dremel for softening sharp edges and eliminating surface scratches during initial polishing stages.

Combined with emery paper, these motors help you achieve scratch-free surfaces that form the foundation of quality craftsmanship.

Rather than investing in larger bench polishers immediately, you can streamline your polishing process with these compact alternatives.

They’re cost-effective solutions that deliver professional results while you’re building your jewelry-making expertise and determining your specific needs.

Rubber Burrs for Surface Smoothing and Scratch Removal

Precision matters most when smoothing jewelry surfaces, and rubber burrs deliver the control you need for professional-quality results.

These versatile tools transform your polishing workflow by tackling different surface challenges effectively.

Medium rubber burrs excel at softening sharp edges on jewelry pieces, ensuring a smoother touch and professional finish.

You’ll find extra fine rubber burrs eliminate surface scratches efficiently, functioning like emery paper when paired with your Dremel or pendant motor.

Rubber burrs streamline your initial polishing stages, delivering smoother finishes quickly and effectively.

They’re game changers for achieving better results in less time.

You can use them across various jewelry applications, including stone setting work.

When combined with appropriate polishing compounds, these tools enhance your jewelry’s aesthetic while maintaining the versatility beginners need for quality craftsmanship.

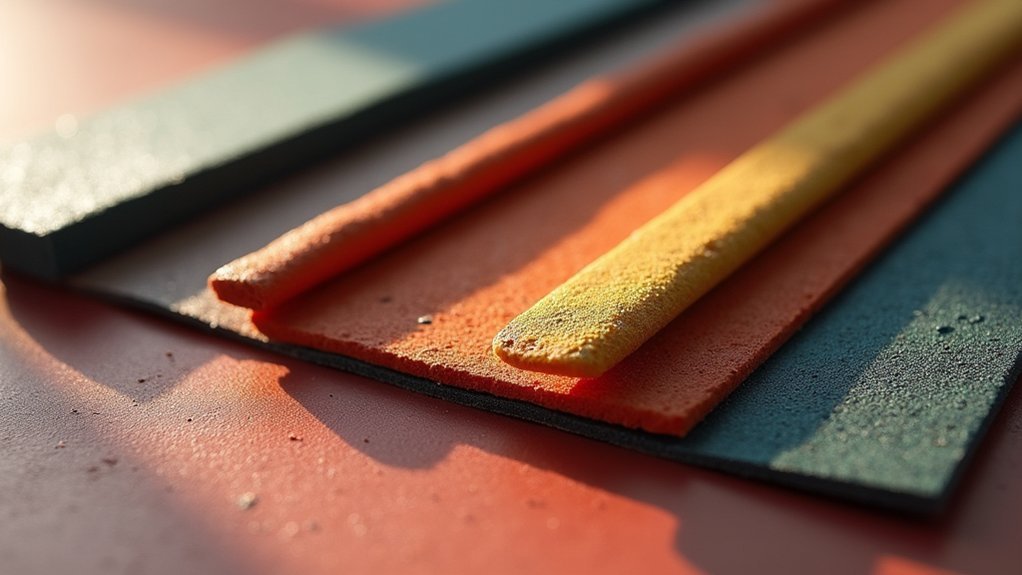

Emery Paper and Sanding Sticks for Initial Finishing

After achieving smooth surfaces with rubber burrs, emery paper becomes your next ally for creating the foundational finish that sets up successful polishing.

You’ll need to apply firm pressure while rubbing to effectively prepare your pieces for finer stages ahead.

Essential emery paper and sanding tools include:

- Emery paper grades – Choose from 500, 1200, and 2000 grits to guarantee scratch-free surfaces during initial finishing

- Flat emery sanding sticks – Cost-effective at $1.69 per mandrel, available in 240-1000 grits for removing file marks and excess solder

- Inside ring sanding buffs – Feature vertical sandpaper flaps for even coverage, available in 80-320 or 600-1500 grit ranges

- Combination approach – Use both emery paper and sanding sticks together for thorough foundational finishing

Mop Heads and Buffing Wheels for High-Shine Results

Two specialized mop heads will transform your jewelry from acceptable to exceptional, delivering the mirror-like finish that distinguishes professional work.

Calico mop heads excel at buffing while effectively removing fire scale and light scratches. They’ll streamline your workflow by reducing future polishing requirements. Leather mop heads provide gentle touch for buffing out imperfections without damaging metal surfaces.

| Mop Head Type | Best Use | Key Benefit |

|---|---|---|

| Calico | Initial buffing | Removes fire scale efficiently |

| Leather | Final polishing | Gentle on metal surfaces |

Your polishing wheel setup should incorporate both varieties for maximum versatility. This combination allows you to achieve consistent shine across different metal types while maintaining efficiency. These tools are essential for beginners seeking professional-quality results that rival experienced jewelers’ work.

Polishing Compounds and Finishing Cloths for Professional Luster

The right polishing compounds will elevate your jewelry’s finish from good to genuinely professional.

Professional-grade polishing compounds transform amateur jewelry finishes into results that rival expert craftsmanship.

You’ll need specific compounds matched to your metal types and desired results.

Essential polishing supplies include:

- Luxi Red and Luxi Blue compounds – Luxi Blue produces less dust for cleaner application

- Euroluster and Zip Buffing Compound – Tailored formulations that minimize scratching risks

- Fabulustre Jewelry Polishing Cloth – Rouge-impregnated cloth that simplifies buffing

- Two-cloth method – One cloth removes excess rouge, another provides final polish

Polishing Cloths impregnated with compounds streamline your workflow considerably.

The two-cloth technique prevents contamination that can ruin your finish.

Consider purchasing complete polishing kits that bundle specialized compounds with appropriate buffs—they’ll give you professional-quality results without requiring extensive experience.

Frequently Asked Questions

What Is the Difference Between Buffing and Polishing Jewelry?

You’ll polish jewelry first using abrasive compounds to remove scratches and create smoothness, then you’ll buff with softer materials like cotton wheels to achieve that final high-gloss, mirror-like shine.

How Can I Polish My Jewelry at Home?

You’ll start with 500-2000 grit emery paper to remove scratches, then use rubber burrs on a Dremel for smoothing edges, and finish with calico mops and polishing compounds for brilliant shine.

What Do Jewelers Use to Polish?

You’ll find jewelers use Dremel or pendant motors with rubber burrs for initial polishing, followed by emery paper grades, then calico or leather mop heads with compounds like Luxi Red or Blue.

Can You Use a Dremel to Polish Jewelry?

You can absolutely use a Dremel to polish jewelry. It’s versatile with rubber burrs and mop attachments, eliminates sharp edges, smooths scratches, and lets you experiment without investing in expensive bench polishers.

In Summary

You’ve now got everything you need to transform dull jewelry into gleaming pieces. Start with Dremel motors for versatility, use rubber burrs to smooth imperfections, then progress through emery papers for initial finishing. Don’t skip the mop heads and buffing wheels—they’re essential for that mirror shine you’re after. Finally, apply quality compounds with finishing cloths for professional results. With these five tools, you’ll polish like a pro in no time.

Leave a Reply