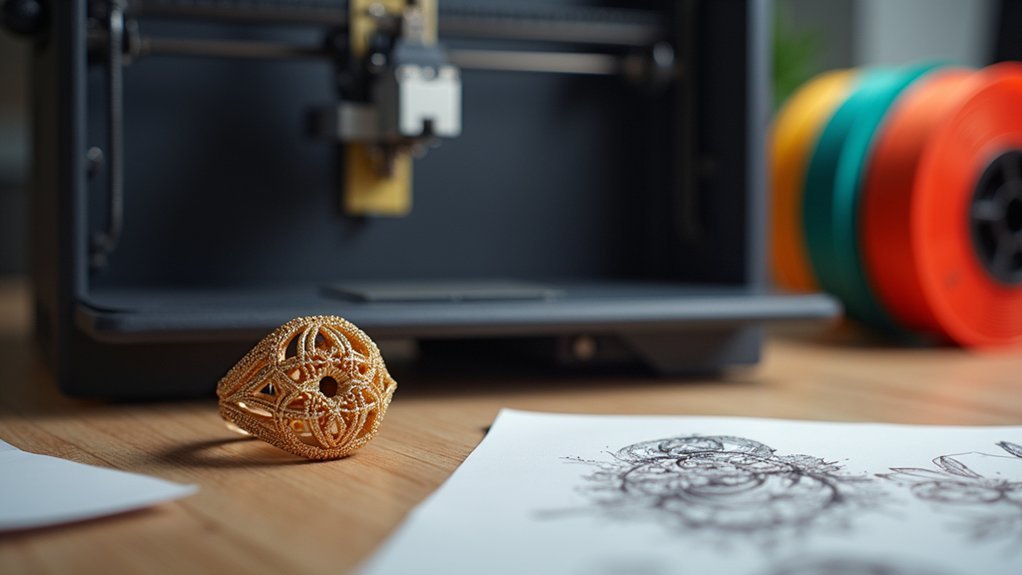

You’ll find budget 3D printers offer an incredibly cost-effective entry into jewelry making, with startup costs ranging from just €200-€500 compared to thousands for traditional equipment. These LCD printers achieve professional 22-35 µm resolution, delivering intricate details that rival expensive systems while reducing prototyping costs from $125 to just $4. You can print 10-20 pieces simultaneously, test market viability quickly, and scale gradually without risking substantial investment. Continue exploring to discover specific techniques that maximize your creative potential.

Cost-Effective Entry Point for Jewelry Entrepreneurs

Three years ago, starting a jewelry business required thousands of dollars in equipment and traditional manufacturing partnerships that put custom design out of reach for most entrepreneurs.

Today, budget 3D printers like the Phrozen LCD series have revolutionized the jewelry-making process by offering professional-quality output at accessible price points.

You can now prototype designs for just $4 instead of the traditional $125, dramatically reducing your financial barriers to entry. This cost reduction lets you experiment freely while creating jewelry that meets professional standards.

Budget printers enable you to produce intricate jewelry pieces without expensive manufacturing partnerships, giving you complete creative control over your designs and allowing you to launch your business with minimal upfront investment.

LCD Technology Delivers Professional-Quality Results

While traditional jewelry manufacturing required expensive industrial equipment to achieve fine detail, LCD 3D printers now deliver professional-quality results at budget-friendly prices.

You’ll achieve resolutions as fine as 22 µm, enabling intricate designs that rival expensive DLP or SLA systems. LCD technology produces smooth surfaces and captures delicate features essential for highly detailed jewelry models.

Your budget LCD printer can handle complex geometries and fine textures that traditional methods struggle with.

Budget LCD printers excel at intricate jewelry details and complex shapes that challenge conventional manufacturing techniques.

You’ll benefit from fast printing speeds, allowing multiple pieces per session while maintaining exceptional quality. The technology works seamlessly with specialized castable resins designed for jewelry applications, mimicking traditional wax models perfectly.

This means you can create professional-grade prototypes and production pieces without compromising quality or breaking your budget.

Rapid Prototyping Reduces Design Development Time

You’ll dramatically accelerate your jewelry design process when you switch from traditional prototyping methods that take weeks to 3D printing that delivers results in hours.

Your design iterations become incredibly cost-effective, dropping from $125 per prototype to just $4, which means you can afford to test multiple variations without breaking your budget.

This speed and affordability combination lets you refine designs quickly and bring finished pieces to market in weeks rather than months.

Speed Over Traditional Methods

Budget 3D printers revolutionize jewelry design development by slashing prototyping time from weeks to mere hours.

You’ll experience unprecedented speed advantages over traditional methods that once required extensive manual craftsmanship and multiple revisions.

Traditional jewelry-making processes typically consume weeks to finalize a single design, but you’ll complete rapid iterations within days or hours using budget 3D printers.

Your CAD software integration enables instant design adjustments and modifications, streamlining your creative workflow considerably.

You can print multiple patterns simultaneously, dramatically enhancing productivity compared to conventional one-piece-at-a-time approaches.

This speed advantage proves especially valuable for custom jewelry projects where clients demand quick turnarounds.

Your attention to detail remains uncompromised while achieving faster results, making limited-edition pieces more feasible for your business.

Cost-Effective Design Iterations

When traditional jewelry prototyping drains your budget at $125 per piece, budget 3D printers transform your economics by delivering iterations for just $4 each.

This dramatic cost reduction enables you to explore multiple design variations without financial constraints, making cost-effective design iterations a reality for your jewelry business.

You’ll accelerate your development timeline from weeks to mere hours, allowing rapid testing of different concepts.

Your printed jewelry prototypes can serve directly as masters for rubber molding processes, eliminating expensive intermediate steps.

This efficiency lets you create multiple patterns simultaneously, maximizing your printer’s output while minimizing per-piece costs.

The financial freedom budget printers provide means you can respond quickly to customer feedback and market trends without risking significant capital investment.

Multiple Jewelry Pieces in Single Print Sessions

Since efficiency drives profitability in jewelry making, modern budget 3D printers like the Phrozen Sonic Mini 4K and 8K revolutionize how you approach production by enabling multiple pieces to print simultaneously.

You’ll maximize your build area by printing 10-20 rings per plate with the Sonic Mini 8K, greatly reducing time spent on individual pieces. This capability becomes one of the first game-changers you’ll notice when moving from traditional methods.

By layering multiple designs effectively, you’ll decrease material costs while increasing output volume considerably.

Please visit manufacturer specifications to understand your printer’s capacity limitations. Your production workflow becomes streamlined as you eliminate labor-intensive individual piece creation.

Always check your Privacy Policy when uploading designs to cloud-based slicing software for batch printing efficiency.

Castable Resins Enable Traditional Lost Wax Casting

Although traditional lost wax casting has remained jewelry making’s gold standard for centuries, castable resins now bridge the gap between modern 3D printing and time-tested techniques.

You’ll find that Castable Jewelry Violet Resin mimics traditional wax properties perfectly, allowing seamless integration into your existing lost wax casting workflow.

Budget 3D printers enable you to create intricate designs that would be nearly impossible to handcraft.

You’re looking at massive cost savings too – prototyping expenses drop from approximately $125 to just $4 per model.

The precision you’ll achieve with castable resins lets you produce complex geometries and fine details effortlessly.

When you use budget printers like Phrozen models, you can print multiple jewelry pieces simultaneously, dramatically reducing production times while maintaining the traditional casting methods you trust.

Lower Investment Risk for New Jewelry Businesses

You’ll find that budget 3D printers dramatically reduce your startup costs, often requiring less than 500 euros compared to thousands for professional equipment.

This lower financial barrier lets you enter the jewelry market without risking substantial capital, making it easier to test whether your designs resonate with customers.

You can experiment with different styles and gauge market demand before committing to expensive traditional manufacturing methods.

Minimal Capital Requirements

When you’re launching a jewelry business, budget 3D printers dramatically reduce your financial risk by requiring only €200 to €500 in initial equipment investment—a fraction of what high-end models demand.

This minimal capital requirement transforms how you can approach your startup strategy:

- Preserve cash flow – You’ll keep more funds available for essential business elements like marketing campaigns, premium materials, and inventory expansion.

- Test market viability – You can validate your jewelry designs and target audience without risking thousands of euros upfront.

- Scale gradually – Start small and reinvest profits into upgraded equipment as your customer base grows.

You’ll discover that many budget-friendly printers still deliver impressive resolution and detail quality, enabling you to create intricate jewelry pieces while maintaining lean operational costs throughout your business development phase.

Testing Market Viability

Beyond preserving your startup capital, budget 3D printers offer an ideal testing ground for validating jewelry designs before committing to large-scale production. You can rapidly prototype unique pieces and gauge consumer interest without considerable financial exposure.

| Testing Method | Timeline |

|---|---|

| Traditional prototyping | 2-3 weeks |

| Budget 3D printing | 2-3 days |

| Consumer feedback cycles | Hours to days |

This accelerated development process lets you experiment with customized designs at minimal cost. You’ll produce limited-edition pieces to test market demand effectively, avoiding the risk of unsold inventory that plagues many new jewelry businesses.

When consumer feedback arrives, you can pivot your designs immediately. This flexibility guarantees you’re creating pieces people actually want to buy, greatly reducing your business risk.

Compact Designs Perfect for Small Studio Spaces

Space constraints shouldn’t limit your jewelry-making ambitions, especially when budget 3D printers like the Phrozen Sonic Mini series offer compact designs that maximize your workspace efficiency.

These printers fit seamlessly into any studio environment without overwhelming your valuable workspace.

The Sonic Mini series delivers impressive capabilities within remarkably small footprints:

- Desktop-friendly dimensions – The 4K model offers 6.1 inches of printing area while the 8K provides 7.1 inches, both fitting comfortably on workbenches.

- Lightweight portability – Easy relocation means you can reorganize your studio layout whenever needed.

- Multi-unit flexibility – Their affordability lets you invest in multiple printers for different tasks without sacrificing precious studio space.

You’ll appreciate how these compact powerhouses integrate into home workshops or professional studios, giving you professional-grade printing capabilities without the spatial demands of larger industrial machines.

High-Resolution Prints Capture Intricate Details

While compact size makes these printers studio-friendly, their impressive resolution capabilities truly set them apart for jewelry creation. Budget printers like the Phrozen Sonic Mini 4K deliver 4K resolution that captures every intricate detail your designs demand.

You’ll achieve 35 µm XY resolution, enabling precise rendering of complex shapes and delicate features that make jewelry truly exceptional. The 6.1-inch printing area lets you produce multiple pieces simultaneously without compromising quality.

Advanced technologies in these affordable machines create smoother surfaces and higher dimensional accuracy, elevating your jewelry’s aesthetic appeal. You can experiment with unique, complex designs while maintaining professional-grade outputs.

This combination of precision and affordability means you’re not sacrificing detail for budget—you’re getting both high-resolution results and creative freedom.

Customization Capabilities for Unique Client Requests

When clients approach you with unique jewelry requests, budget 3D printers transform these personalized visions into reality with remarkable precision and affordability.

These printers offer exceptional customization capabilities that revolutionize how you create bespoke pieces. Your digital design process enables rapid iterations based on client feedback:

- Quick Design Modifications: CAD software allows you to make instant adjustments without expensive prototyping.

- Cost-Effective Personalization: Create custom pieces for approximately $4 instead of $125 using traditional methods.

- Batch Customization: Produce multiple unique designs simultaneously in single printing sessions.

With castable resins like Phrozen Castable Jewelry Violet Resin, you’ll replicate traditional jewelry-making aesthetics while maintaining intricate details.

This combination of affordability, speed, and precision means you can fulfill diverse client requests efficiently, turning specialized commissions into profitable opportunities rather than costly challenges.

Reduced Material Waste Compared to Traditional Methods

When you switch to budget 3D printing for jewelry making, you’ll dramatically cut material waste through precise resin usage that creates only what’s needed.

Unlike traditional casting methods that require excess material for sprues and runners, 3D printing uses minimal support material that can often be eliminated entirely through smart design orientation.

You can also make design adjustments digitally before printing, preventing the costly material waste that comes from discovering flaws in physical prototypes.

Precise Resin Usage

Budget 3D printers revolutionize jewelry making through their precise resin dispensing system, which dramatically cuts material waste compared to traditional crafting methods.

When you’re using traditional techniques, you’ll often discard excess wax or metal during the crafting process, leading to significant material loss.

With budget 3D printers, you’ll benefit from:

- Layer-by-layer precision – Accurate reproduction eliminates trial and error, reducing overall material consumption

- Digital optimization – CAD software lets you perfect designs before printing, ensuring you use only necessary resin amounts

- Batch printing efficiency – Models like the Phrozen Sonic Mini series allow simultaneous printing of multiple pieces, minimizing resin per item

You’ll find this controlled, resource-efficient approach gives you more value from every drop of resin while creating intricate designs.

Minimal Support Material

Beyond precise resin dispensing, budget 3D printers excel at minimizing support material requirements, further reducing waste in your jewelry-making workflow.

LCD models particularly shine here, requiring minimal supports compared to traditional casting methods that often demand extensive structural assistance.

You’ll find digital design capabilities allow precise support placement only where absolutely necessary, unlike conventional techniques that waste material in unnecessary areas.

Modern castable resins enhance this efficiency, producing cleaner prints with diminished support needs and reduced post-processing waste.

Your budget printer can handle intricate jewelry designs with easily removable supports, eliminating the excess material that traditional methods often leave attached to finished pieces.

This efficient material usage translates directly to cost savings, consuming less resin per project than conventional jewelry fabrication techniques.

Digital Design Adjustments

Digital modifications transform how you approach jewelry design, enabling unlimited revisions without touching a single gram of precious metal or gemstone.

You’ll drastically cut material waste compared to traditional methods where each prototype consumes expensive resources.

- Virtual iterations – You can refine designs digitally using CAD software, testing multiple variations before committing to any physical material.

- Precise adjustments – Make exact modifications without the costly trial-and-error process that wastes precious metals in conventional jewelry making.

- Rapid experimentation – Quickly identify successful design elements while eliminating unsuccessful attempts that would otherwise result in material loss.

This efficient approach lets you perfect your designs virtually, ensuring you only use materials for final, optimized pieces.

You’ll maintain creative freedom while supporting sustainable practices through reduced environmental impact.

Easy Learning Curve for Jewelry Artisans

While traditional jewelry making requires years to master complex techniques, 3D printing technology offers a remarkably gentle introduction for artisans entering the digital domain. Budget printers like Phrozen models feature intuitive touch panels that’ll guide you through each process step. You won’t need extensive technical knowledge to start creating detailed jewelry pieces.

| Learning Advantage | Benefit |

|---|---|

| Affordable experimentation | Practice without financial pressure |

| User-friendly interfaces | Quick operation mastery |

| Online community support | Immediate troubleshooting help |

| Lower initial investment | More budget for materials and software |

You’ll find abundant tutorials specifically designed for budget printer users. This accessibility means you can focus your resources on premium materials and design software rather than expensive equipment, accelerating your creative development in digital jewelry making.

Scalable Production Without Major Equipment Upgrades

As your jewelry business grows, budget 3D printers like the Phrozen Sonic Mini series let you scale production without breaking the bank on equipment upgrades.

You’ll multiply your output capacity while maintaining the same high-quality standards that intricate jewelry designs demand.

Here’s how budget printers support your expansion:

- Multiple simultaneous prints – Print dozens of rings, pendants, or earrings in a single batch

- Compact workspace efficiency – Scale up production without requiring larger facilities or additional floor space

- Flexible material compatibility – Switch between various castable resins to accommodate different techniques and customer requests

You can adapt quickly to market trends and customer preferences without substantial investment.

When demand spikes for personalized pieces or trending designs, your budget printer handles increased volume seamlessly, making business growth both achievable and profitable.

Frequently Asked Questions

Is It Worth Getting a Cheap 3D Printer?

You’ll find cheap 3D printers worthwhile if you’re starting out or experimenting. They offer decent quality for learning, prototyping, and hobby projects without major investment, though they’ll have limitations compared to premium models.

Can You Make Jewellery With a 3D Printer?

You can definitely make jewelry with a 3D printer using CAD software and castable resins. You’ll create intricate designs quickly, prototype faster than traditional methods, and even use models for lost wax casting processes.

Can You Make Money With a Cheap 3D Printer?

You can definitely make money with a cheap 3D printer by creating custom jewelry, rapid prototyping, and producing limited-edition pieces that command higher prices in niche markets.

How Much Should I Spend on a Good 3D Printer?

You should spend $200-500 on a quality 3D printer that’ll deliver professional results without breaking your budget. This range offers high-resolution printing capabilities perfect for detailed work while maintaining affordability.

In Summary

You’ll find budget 3D printers transform your jewelry business without breaking the bank. You’re getting professional results with LCD technology while cutting development time through rapid prototyping. You can produce multiple pieces simultaneously, work with castable resins for traditional methods, and offer custom designs that set you apart. You’re reducing waste, learning quickly, and scaling production efficiently. Budget 3D printing isn’t just affordable—it’s your competitive advantage in modern jewelry making.

Leave a Reply