You’re about to discover a revolutionary jewelry technique that’s transforming how artisans create the finest decorative details. Micro granulation without traditional flux eliminates the messy residues and unpredictable results that’ve plagued craftspeople for centuries. Instead of relying on chemical fluxes, you’ll harness precise temperature control and surface tension physics to achieve perfect metal fusion. This method produces cleaner bonds, reduces contamination risks, and opens possibilities that traditional approaches simply can’t match.

Understanding Micro Granulation Fundamentals

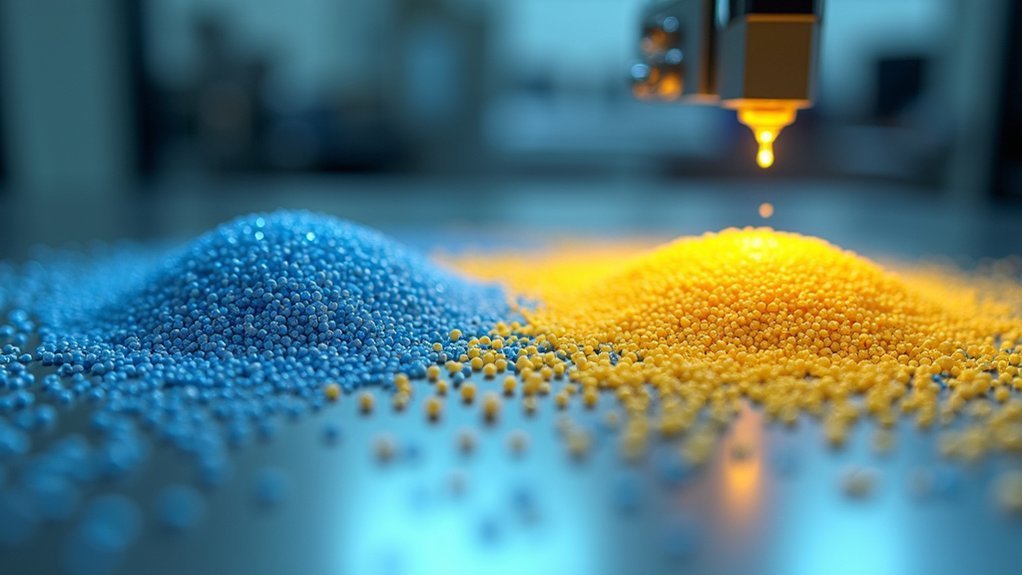

While traditional granulation relies heavily on flux to achieve proper bonding, micro granulation fundamentals center on creating exceptionally small granules—typically under 0.5 mm in diameter—through precise colloidal soldering or direct fusing methods.

You’ll work with granules made from the same alloy as your base metal, ensuring compatibility during heating and achieving seamless adhesion. This technique demands meticulous placement of each tiny element to create intricate designs that showcase exceptional detail and precision.

Your success depends on mastering temperature control and timing, as excessive heat can distort your carefully arranged patterns.

Unlike conventional methods, you’ll rely on the inherent properties of matching alloys rather than external bonding agents, creating cleaner, more refined results in your jewelry and decorative metalwork.

Historical Evolution From Traditional Flux Methods

You’ll find that ancient Etruscan craftsmen pioneered granulation without hard solder, mastering complex techniques that modern artisans still study today.

As metalworking evolved, the development of colloidal soldering introduced mixtures of tragacanth gum and copper salts as alternatives to traditional flux methods.

Today’s micro granulation has shifted toward flux-free approaches that give you greater precision and eliminate contamination risks in your finished pieces.

Ancient Etruscan Techniques

Although today’s jewelers rely heavily on modern flux compounds, ancient Etruscan craftsmen mastered granulation through revolutionary techniques that completely bypassed traditional flux materials.

These skilled artisans developed colloidal soldering during the 8th to 3rd centuries B.C., using a mixture of tragacanth gum and copper salts instead of conventional flux. You’d find their jewelry technique fascinating—they achieved precise granule placement through meticulous heating without any traditional flux assistance.

The Etruscan approach to granulation in ancient times produced intricate designs that distinguished their work from contemporaries. Their fine powder granulation method created sophisticated jewelry pieces, as archaeological evidence from Etruscan sites demonstrates.

Unfortunately, when Etruscan craftsmanship declined in the 3rd to 2nd centuries B.C., this advanced knowledge was largely lost to history.

Colloidal Soldering Development

Before modern flux compounds dominated metalworking, ancient artisans pioneered colloidal soldering as a revolutionary alternative that transformed granulation techniques. You’ll discover this Etruscan innovation used a colloidal mixture of tragacanth gum and copper salts instead of traditional flux or solder. The technique enabled precise fusing of granules to sheet metal at 890°C eutectic temperatures.

| Aspect | Traditional Flux | Colloidal Method |

|---|---|---|

| Temperature | Variable | 890°C precise |

| Residue | Leaves deposits | Clean fusion |

| Bond Quality | Inconsistent | Superior strength |

You can achieve stunning results without flux complications that often dislodged granules during heating. The melting temperature the granules required remained consistent, allowing craftsmen to create intricate Etruscan jewelry. Ancient Greeks also adopted this method, producing remarkable pieces like First Century B.C. Indian earrings that showcase colloidal soldering’s effectiveness in detailed granulation work.

Modern Flux Alternatives

As metalworking technology advanced through the Industrial Revolution, craftspeople began experimenting with synthetic compounds that offered greater precision than borax and pine resin.

You’ll find that modern materials science has revolutionized granulation through polymer-based binders that eliminate traditional flux residues while maintaining superior control over melting points. These liquid flux alternatives feature low surface tension properties, ensuring better wetting and stronger adhesion without granule displacement during heating.

You can now utilize flux-free soldering techniques that rely solely on controlled heat and pressure, streamlining your workflow while preserving metal integrity.

Contemporary adhesive agents create strong bonds between granules and base metals, reducing contamination risks that plagued historical methods. This evolution from natural substances to synthetic alternatives gives you enhanced precision and cleaner results in micro granulation applications.

Temperature Control and Heat Management Techniques

You’ll find that mastering precise heat application becomes your most critical skill when working without traditional flux in micro granulation.

Your torch control must remain steady and consistent, as even minor temperature fluctuations can cause granules to overheat and lose their delicate spherical form.

You can’t afford to rush the heating process—gradual temperature increases will give you the control needed to reach that perfect fusing point without compromising your metal’s integrity.

Precise Heat Application

Since micro granulation without flux relies entirely on precise metallurgical reactions, temperature control becomes the most critical factor determining your success or failure. The eutectic soldering temperature range of approximately 890°C requires exact heat management to achieve proper fusing without traditional flux assistance.

Your controlled application technique should follow these essential steps:

- Use a small torch tip to concentrate heat precisely on individual granules, preventing unwanted sphere formation.

- Adjust your distance from the heat source to maintain ideal temperatures while avoiding reticulation damage.

- Employ graphite tools to direct heat exactly where needed for uniform granulation results.

- Monitor visual cues continuously, watching for color changes in both granules and base metal during the granulation process.

This precise heat application guarantees successful outcomes through careful temperature management.

Avoiding Metal Overheating

Building on these precise heat application methods, overheating poses the greatest threat to your micro granulation work, especially when working with sterling silver’s lower melting point compared to pure gold.

Unlike traditional flux-solder techniques, granules must fuse at temperatures just below their melting point, requiring exceptional temperature control. You’ll need to watch for visual cues—when granules begin to glow, immediately adjust your flame intensity.

Indirect heating methods prove invaluable here; position your torch to warm the surrounding area rather than applying direct heat application to the granules themselves.

Using a copper block as a heat sink helps distribute thermal energy evenly, preventing localized hot spots that cause unwanted reticulation or complete melting.

Surface Tension Physics in Fluxless Granulation

When you eliminate traditional flux from the granulation process, surface tension becomes your primary ally in creating successful bonds between metal granules. This natural adhesive property of molten metals transforms how you approach fluxless granulation.

Understanding surface tension physics helps you master this technique:

Mastering surface tension physics transforms your granulation technique from traditional flux dependency to precision metalwork artistry.

- Control precise heat application – You’ll need careful temperature management to activate surface tension without excessive melting.

- Maintain consistent granule size – Uniform pieces ensure predictable adhesion patterns across your work surface.

- Time the coalescence perfectly – Surface tension creates ideal bonding windows during the heating process.

- Leverage natural metal properties – The liquid metal’s inherent surface tension eliminates traditional flux dependency.

This approach demands exceptional craftsmanship, as you’re working with metal’s fundamental physical properties to achieve intricate granulation effects.

Metal Preparation and Cleaning Protocols

Before achieving successful fluxless granulation, you must establish pristine metal surfaces that allow natural adhesion forces to work effectively.

Start your metal preparation by thoroughly cleaning the surface of the metal using ultrasonic cleaners or warm soapy water, followed by distilled water rinsing. This removes dirt, grease, and oxidation that prevents proper granules adhesion.

For copper and other metals requiring enhanced cleanliness, use pickling solutions like a diluted acid bath to eliminate surface oxides and boost reactivity.

You’ll need completely dry surfaces before applying binding agents or starting granulation—moisture creates contamination issues.

Don’t forget cleaning your tools and workspace regularly. Foreign materials interfere with micro granulation success.

Proper contaminants removal guarantees ideal results in your fluxless process.

Granule Creation and Sizing Methods

Creating uniform granules forms the foundation of successful micro granulation, whether you’re working with high-karat gold or silver alloys that match your base metal’s composition.

The diameter of the granules directly impacts your final piece’s aesthetic quality and structural integrity.

Small granules for granulation are usually made using these methods:

- Roll a thin sheet of metal into tiny squares, then fire them to form spheres with consistent sizing.

- Coil fine wires into jump rings before heating to create uniform granules through controlled melting.

- Coat pieces in charcoal powder during firing to prevent sticking and guarantee even heat distribution.

- Sort granules by size after creation to achieve uniformity across the metal surface you’re decorating.

Placement Strategies for Precise Assembly

Once you’ve created your granules, positioning them accurately becomes the most critical phase of micro granulation work. Effective placement strategies begin with organizing your granules by size and shape in triangular gem sorting trays, ensuring easy access during the assembly process.

You’ll need precision tools like tweezers and fine probes for accurate positioning on your substrate. Since you’re working without traditional flux, prepare your base surface to be completely clean and dry to prevent contamination.

A slightly dampened brush becomes invaluable for picking up individual granules, using surface tension to your advantage. This technique provides better control than dry placement methods.

Remember that precise placement requires patience – rushing this stage compromises the entire project’s success and negates your careful granule preparation work.

Troubleshooting Common Fusing Challenges

Even with perfect granule placement, fusing problems can derail your micro granulation project at the final stage. Without traditional flux, you’ll face unique challenges that require specific troubleshooting approaches. Success depends on understanding how surface tension, heating control, and timing work together in this delicate process.

- Control your heat source carefully – Use propane or natural gas torches instead of oxy-acetylene to prevent overheating that causes reticulation or excessive melting of thin granules.

- Monitor surface tension balance – Apply distilled water or surface treatments to stabilize granules during fusing when flux isn’t available.

- Adjust heating timing – Underheating prevents proper fusion, while overheating destroys delicate work.

- Practice patience – Multiple fusing attempts may be necessary to achieve desired results.

Frequently Asked Questions

What Is Micro Granulation?

You’ll create tiny metal granules under 1mm diameter for intricate jewelry designs. You’ll fuse these small spheres onto surfaces using precise heating techniques, achieving fine textures and detailed patterns that enhance your metalwork’s aesthetic quality.

What Are the Three Types of Granulation?

You’ll encounter three main granulation types: hard soldering using lower-melting solder through capillary action, fusing that relies purely on heat without flux, and ancient colloidal soldering employing copper salts with tragacanth gum.

What Is Melt Granulation an Alternative to Traditional Granulation Techniques?

You’ll find melt granulation replaces wet and dry granulation by using heat instead of liquid binders or mechanical compression, eliminating moisture concerns while creating uniform granules with better flowability for pharmaceutical applications.

What Is the Granulation Technique of Jewelry?

You’ll attach tiny metal spheres called granules to jewelry surfaces, creating decorative patterns through fusing techniques. You’re creating intricate designs without traditional flux, requiring precise positioning and careful temperature control for proper bonding.

In Summary

You’ve now mastered micro granulation without traditional flux, transforming your metalworking approach through precise temperature control and advanced surface preparation. You’re creating cleaner bonds while preserving ancient craftsmanship techniques with modern innovations. You’ll continue developing your skills by practicing granule placement and troubleshooting fusion challenges. You’re part of an evolving tradition that honors historical methods while embracing contemporary materials and tools for superior results.

Leave a Reply