You’ll achieve superior casting results with precious metals when you choose centrifugal casting because it generates up to 100Gs of force, ensuring uniform molten metal distribution and eliminating mid-wall inconsistencies. This method drives impurities toward the bore area while promoting outside-in solidification that prevents shrinkage cavities and gas pockets. You’ll get exceptional metal density, reduced micro porosity, and smooth surfaces that minimize post-processing time. The extensive advantages extend far beyond these fundamental benefits.

How Centrifugal Force Eliminates Casting Defects in Precious Metals

When you’re casting precious metals, centrifugal force becomes your most powerful ally in eliminating defects that plague traditional casting methods. The process generates up to 100Gs, pushing molten metal uniformly into molds and preventing mid-wall inconsistencies.

You’ll achieve superior results because the solidification process works from outside surfaces inward, eliminating shrinkage cavities, gas pockets, and blowholes that compromise quality.

The high centrifugal force drives impurities toward the bore area, creating a natural refining effect that produces defect-free components. This directional solidification under pressure enhances mechanical properties while reducing micro porosity.

You won’t need risers or feed points, which eliminates trapped porosity risks. The result? High integrity parts with exceptional soundness that meet the demanding standards precious metals require.

Speed and Efficiency Advantages for Platinum and Gold Casting

Beyond achieving superior quality, centrifugal casting dramatically accelerates your production timeline when working with platinum and gold. You’ll experience rapid injection of molten metal into molds, greatly reducing casting time for these high melting point precious metals. The continuous centrifugal force guarantees uninterrupted liquid metal supply, promoting faster solidification.

| Advantage | Platinum Casting | Gold Casting |

|---|---|---|

| Injection Speed | Rapid filling | Quick penetration |

| Production Rate | Multiple parts simultaneously | Batch efficiency |

| Surface Quality | Smooth finish | Minimal post-processing |

| Density Achievement | High-density parts | Superior compaction |

Your efficiency increases through simultaneous multi-part production capabilities. Centrifugal casting delivers high-density parts with smooth surfaces, eliminating extensive post-processing requirements. This speed and efficiency combination makes it ideal for professional jewelers requiring quality precious metals casting.

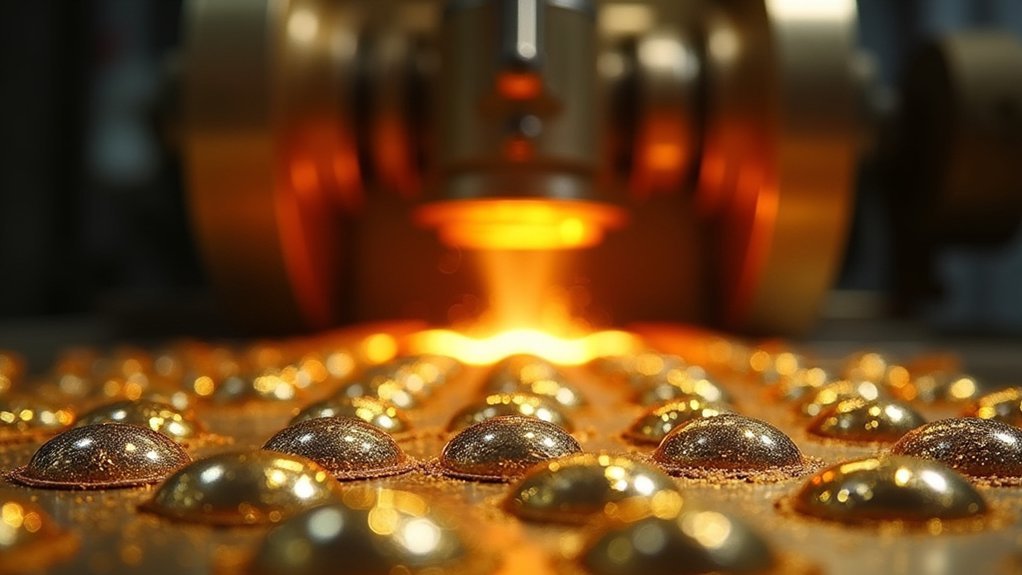

Superior Metal Density and Surface Quality Through Centrifugal Action

As centrifugal forces reach up to 100Gs during the casting process, you’ll achieve exceptional metal density that surpasses traditional casting methods for precious metals.

This powerful centrifugal action effectively isolates impurities while promoting directional solidification from the outside surface inward, eliminating problematic mid-wall defects.

You’ll notice superior surface quality in your finished pieces, as the process reduces micro porosity and prevents shrinkage cavities and gas pockets.

The centrifugal casting technique delivers smooth surfaces that require minimal post-processing, enhancing your jewelry’s visual appeal while reducing production time.

When working with platinum and gold, this metal casting method guarantees consistently high-quality components.

You’ll produce multiple intricate jewelry casting designs simultaneously while maintaining exceptional density and surface finish standards throughout your precious metals production.

Equipment Requirements for Precious Metal Centrifugal Casting

Since achieving ideal results in centrifugal casting depends heavily on your equipment selection, you’ll need an extensive setup that includes several critical components.

Your centrifugal casting machine forms the foundation, featuring a robust centrifuge body designed to handle high melting point metals like gold and platinum.

You’ll also require a sophisticated mold making system using high-temperature resistant materials that withstand intense centrifugal forces during the casting process.

Essential tools include small kilns for heating precious metals, propane torches, sprue cutters, and digital scales for precise measurements.

Wax injectors help create accurate patterns for vacuum casting applications.

Regular maintenance of vacuum gauges and fuel filters guarantees peak performance.

The Advantages of Centrifugal casting become apparent when your equipment operates smoothly, delivering consistent quality and production efficiency.

Comparing Centrifugal Vs Vacuum Casting Methods for Jewelry Production

When you’re deciding between centrifugal and vacuum casting methods for jewelry production, the choice fundamentally impacts your final product’s quality and manufacturing efficiency.

Centrifugal casting excels with precious metals like platinum and palladium, utilizing centrifugal force to rapidly inject molten metal into molds. You’ll achieve superior dimensional accuracy, tighter tolerances, and smoother surfaces with dense internal structures. This method’s particularly effective when you need to melt high melting point precious metals, minimizing defects like shrinkage cavities.

Vacuum casting offers flexibility for larger production runs and varied flask dimensions, but you’ll face longer cooling times and higher investment material requirements. Your casting machines will produce multiple parts simultaneously with centrifugal methods, enhancing efficiency.

For high-end jewelry applications requiring precision, centrifugal casting consistently delivers better results than vacuum alternatives.

Frequently Asked Questions

What Is the Main Advantage of Centrifugal Casting?

You’ll get consistently defect-free castings without shrinkage cavities or gas pockets because centrifugal force continuously supplies liquid metal during solidification, while effectively isolating impurities for superior quality results.

Which of the Following Is the Main Advantage of Using the Centrifugal Casting Method?

You’ll find centrifugal casting’s main advantage is eliminating mid-wall defects through high centrifugal force. This guarantees consistent quality by reducing shrinkage cavities and gas pockets while creating denser, more structurally sound castings.

What Are the Disadvantages of Centrifugal Casting?

You’ll face limitations with length-to-diameter ratios, increased tooling costs for irregular shapes, safety challenges from higher mold speeds, potential investment material breakage, and dependency on excellent foundry practices for consistent results.

Is Centrifugal Casting Expensive?

You’ll face higher upfront equipment costs with centrifugal casting, but you’ll save money long-term through reduced waste, faster production, less manual labor, and fewer defects requiring rework.

In Summary

You’ll find centrifugal casting delivers unmatched results for your precious metal projects. It eliminates porosity, speeds up production, and creates denser castings with superior surface finishes. While you’ll need specialized equipment, the investment pays off through reduced defects and faster turnaround times. Whether you’re casting platinum or gold, centrifugal force consistently outperforms vacuum methods for jewelry production, giving you the quality and efficiency your business demands.

Leave a Reply