You’ll discover five essential die casting methods that transform fine jewelry production: centrifugal die casting uses rotating cradles to eliminate air bubbles and achieve superior dimensional accuracy in gold and silver work. Vacuum pressure die casting creates vacuum environments that minimize oxidation while enhancing surface quality. Lost wax investment casting starts with detailed wax models for exceptional precision. High-pressure die striking applies 30-50 tons of force for intricate, durable designs. Gravity-fed techniques rely on natural gravitational pull for smooth, defect-free results. Each method offers unique advantages that’ll elevate your jewelry crafting capabilities.

Centrifugal Die Casting for Precious Metals

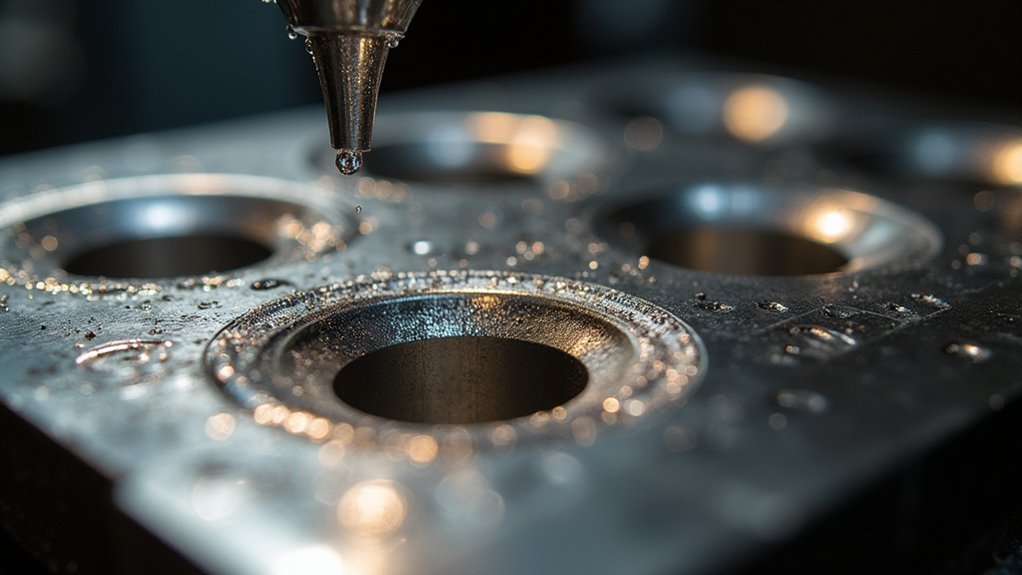

When you’re casting precious metals for fine jewelry, centrifugal die casting offers unmatched precision and quality. This jewelry casting technique places your mold in a rotating cradle, where centrifugal force flings molten precious metal into the cavity.

You’ll achieve superior dimensional accuracy because the rotational force eliminates air bubbles that typically plague other casting methods. The centrifugal casting process compresses your metal during solidification, creating high density components with enhanced strength.

You’ll find this casting method particularly effective for gold and silver work, as it delivers exceptional surface finishes. Modern casting machines require precise alignment between mold and crucible to minimize turbulence.

You can capture intricate details and complex shapes that make this technique ideal for detailed rings, pendants, and other fine jewelry pieces requiring superior quality.

Vacuum Pressure Die Casting Technology

While centrifugal casting relies on rotational force, vacuum pressure casting technology transforms your jewelry production through controlled atmospheric conditions.

You’ll create a vacuum environment that draws molten metal into molds, ensuring complete filling while minimizing air entrapment and oxidation. This process delivers smoother surfaces and eliminates casting defects like bubbles and porosity that compromise fine jewelry quality.

Vacuum environments eliminate air entrapment and oxidation, delivering superior surface quality while preventing bubbles and porosity in fine jewelry casting.

You’ll achieve high dimensional accuracy when casting intricate designs, making this method ideal for detailed pieces requiring precision.

Whether you’re casting gold or platinum, vacuum pressure casting enhances mechanical properties compared to traditional methods. You’ll experience markedly reduced shrinkage cavities and material waste, resulting in higher yield rates.

This technology allows you to cast complex jewelry designs while maintaining superior quality standards throughout your jewelry production process.

Lost Wax Investment Die Casting

Lost wax investment die casting represents the pinnacle of precision casting for fine jewelry production.

You’ll start by creating a detailed wax model that’s encased in a plaster-like investment material. During the burnout cycle, your casting machine heats the investment mold to 1600°F, completely incinerating the wax and creating a hollow cavity with intricate details intact.

When you pour molten metal into this precisely formed cavity, you’ll achieve high dimensional accuracy and exceptional surface quality that’s essential for fine jewelry production.

The investment material captures even the most delicate design elements, ensuring your finished pieces require minimal finishing work.

After cooling and removal, you’ll send these superior castings directly to jewelers for final polishing and stone setting, completing the premium jewelry-making process.

High-Pressure Die Striking Methods

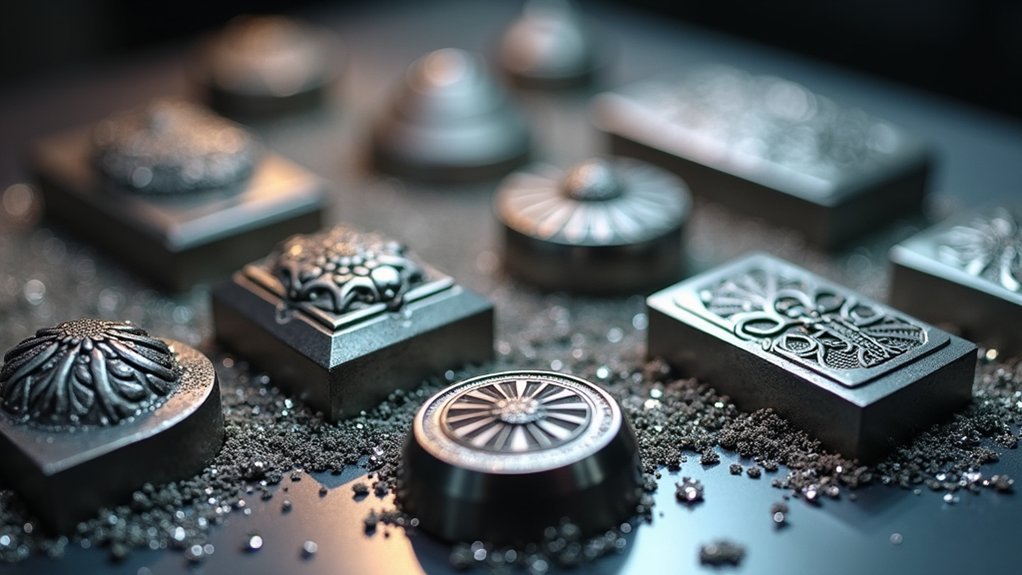

Although casting methods excel at creating hollow forms, high-pressure die striking transforms solid metal through sheer force to produce jewelry’s most durable pieces.

You’ll find this process uses 30 to 50 tons of pressure to compress precious metals like gold and platinum into specialized die molds, creating intricate designs with exceptional detail.

When you choose die striking over traditional casting, you’re getting jewelry with a tighter grain structure that’s incredibly resistant to wear and corrosion.

This method works perfectly for engagement rings, earrings, and pendants where durability matters most.

The process involves forming metal ingots into sheets, then compressing them through specialized machinery.

Metal ingots are transformed into precise sheets through powerful compression machinery, creating the foundation for exceptionally durable jewelry pieces.

While it takes one to several days to complete, you’ll achieve precision and strength that surpasses conventional jewelry manufacturing methods.

Gravity-Fed Die Casting Techniques

Unlike high-pressure striking methods that rely on mechanical force, gravity-fed die casting harnesses natural gravitational pull to deliver molten metal into your mold cavities. This technique excels at creating high-quality jewelry pieces with intricate designs, particularly when working with non-ferrous metals like gold and silver.

Your casting equipment must maintain precise temperature control since these metals have a low melting point. The gravitational flow guarantees smooth filling of complex patterns while minimizing defects in your finished pieces.

| Traditional Challenges | Gravity-Fed Solutions |

|---|---|

| Complex detail reproduction | Gentle, controlled flow |

| Surface imperfections | Superior finish quality |

| Material waste | Efficient metal usage |

This method transforms your jewelry creation process, delivering professional results with reduced stress on delicate mold structures.

Frequently Asked Questions

What Are the Methods of Casting Jewelry?

You’ll use lost wax casting with wax models, centrifugal casting with spinning force, or vacuum casting in closed environments. Each method involves creating investment molds, burning out materials, then pouring molten metal into cavities.

What Are the Methods of Die Casting?

You’ll find die casting uses high-pressure and cold chamber methods. You force molten metal into precision molds under extreme pressure, creating dense, durable pieces with intricate details and superior grain structure.

What Is the Difference Between Die Struck and Cast Jewelry?

You’ll find die-struck jewelry’s denser and stronger than cast pieces. Die-striking uses high pressure compression, creating tighter grain structure and better durability, while casting can produce porosity and weaker integrity.

What Is the Difference Between Die Stamping and Die Casting?

You’ll find die stamping shapes cold metal sheets under high pressure, while die casting pours molten metal into molds. Stamping creates simpler shapes with tighter tolerances, whereas casting produces complex three-dimensional items.

In Summary

You’ve explored five essential die casting methods that’ll transform your jewelry production. Whether you’re working with precious metals through centrifugal casting, achieving precision with vacuum pressure technology, or mastering the traditional lost wax investment process, each technique offers unique advantages. You can now select high-pressure die striking for detailed work or gravity-fed casting for simpler pieces. These methods will elevate your craftsmanship and expand your creative possibilities in fine jewelry making.

Leave a Reply