You’ll calculate jewelry making costs accurately by creating a template that includes material costs, labor time at your hourly rate, packaging expenses, and 10% overhead markup. Track wholesale material prices, multiply your hours by fair wages, and document all overhead expenses like studio rent and tools. Use the base formula: multiply material and packaging costs by four, then add labor and overhead. Regular quarterly reviews guarantee your template stays current with market fluctuations and maintains profitability as your expertise grows.

Essential Components of Jewelry Pricing Templates

Accurate pricing separates profitable jewelry businesses from struggling ones, and your pricing template serves as the foundation for sustainable success.

Your pricing template determines whether your jewelry business thrives or merely survives in today’s competitive marketplace.

Your template must include four essential components: material costs, labor time, packaging expenses, and overhead costs. Material costs encompass metals, gemstones, and findings used in each piece. Labor time should reflect your hourly rate multiplied by actual production time.

Don’t overlook packaging costs—boxes, tags, and protective materials add up quickly. Overhead expenses include website fees, tools, marketing, and studio rent, typically adding 10% to your base price.

Effective pricing strategies also incorporate competitor analysis sections, helping you align with market expectations while maintaining profitability. These components guarantee thorough cost assessment and prevent underpricing that kills profits.

Material Cost Tracking and Wholesale Purchasing Strategies

You’ll dramatically reduce your material expenses by sourcing from wholesale suppliers, who typically offer 20-50% savings compared to retail pricing.

Proper cost documentation becomes essential when you’re tracking these bulk purchases and calculating the exact material costs for each piece you create.

You can’t optimize your pricing strategy without maintaining detailed records of purchase prices per unit and quantities used in your jewelry making process.

Wholesale Sourcing Benefits

Wholesale sourcing transforms your jewelry-making venture from a costly hobby into a profitable business by dramatically cutting material expenses and boosting your bottom line.

When you secure wholesale pricing, you’ll reduce per-unit costs while minimizing shipping expenses through bulk purchases. This strategic approach creates higher profit margins on finished pieces, giving you competitive pricing flexibility.

Building relationships with reputable wholesale suppliers guarantees consistent material quality and availability, preventing production delays that could cost you sales.

You’ll also gain access to exclusive discounts and deals that aren’t available to retail buyers. By leveraging these wholesale advantages, you’re not just saving money—you’re positioning your jewelry business for sustainable growth while maintaining the quality standards your customers expect.

Cost Documentation Methods

While building wholesale relationships sets the foundation for cost savings, implementing systematic cost documentation methods guarantees you’ll capture every penny of those savings and maximize your profitability.

Create a thorough tracking system that documents each item’s purchase price, quantity, and supplier. This detailed record-keeping enables accurate expense monitoring and reveals cost-saving opportunities you might otherwise miss.

Keep all receipts and invoices for materials used—they’re essential for precise pricing calculations and tax documentation.

Review market prices regularly to verify you’re sourcing from the most cost-effective suppliers. The cost of materials fluctuates, so staying informed maintains your competitive edge.

Negotiate with suppliers for discounts or loyalty programs that reduce long-term expenses and boost profitability through sustained wholesale purchasing strategies.

Labor Time Calculation and Hourly Rate Determination

You’ll need to accurately track every hour spent creating your jewelry pieces, from initial design concepts to final packaging.

Setting a fair hourly wage requires calculating your desired annual income plus overhead costs, then dividing by your planned productive work hours.

This systematic approach guarantees you’re compensated properly for your skilled labor while maintaining competitive pricing in the marketplace.

Tracking Production Hours

Since accurate labor cost calculation forms the foundation of profitable jewelry pricing, you’ll need to track every hour spent creating each piece from initial design concepts through final finishing touches.

Maintaining a detailed log separates design, production, and administrative tasks to guarantee nothing’s overlooked when tracking production hours for your handmade jewelry.

Record time spent sketching designs, selecting materials, actual crafting work, and finishing details like polishing or setting stones.

Don’t forget administrative tasks such as photographing pieces, creating product descriptions, or packaging orders.

Use either digital time-tracking apps or simple paper logs to document each activity.

This systematic approach reveals true production costs and helps identify which pieces require excessive time investment, allowing you to adjust pricing or streamline processes for better profitability.

Setting Fair Wages

Determining your worth as a jewelry artisan requires calculating both your actual costs and the value of your skilled labor.

Setting fair wages starts with establishing your hourly rate based on annual overhead divided by profitable working hours. Track your skill level, design complexity, and local market rates when determining compensation between $15-50 per hour.

Apply the 2.5x markup formula: multiply material and packaging costs by 2.5, then add your hourly wage plus 10% overhead. This guarantees you’re compensated for both time and expertise.

Accurately record all labor hours including design, crafting, and finishing phases.

Regularly review your hourly rate as overhead costs change and your expertise grows. Don’t undervalue your artistic skills – fair pricing sustains your craft business long-term.

Overhead Expense Categories and Annual Cost Distribution

Understanding overhead expenses represents a critical step in building a profitable jewelry business, as these annual costs can quickly accumulate to several thousand dollars regardless of how many pieces you create. You’ll need to track expenses like rent, utilities, insurance, marketing, and packaging throughout the year to accurately assess your overhead costs.

| Expense Category | Annual Cost Range |

|---|---|

| Studio Rent & Utilities | $2,400 – $8,000 |

| Insurance & Licensing | $500 – $1,500 |

| Marketing & Trade Shows | $1,000 – $5,000 |

| Tools & Equipment | $800 – $3,000 |

| Packaging & Postage | $600 – $2,000 |

Distribute these overhead costs across your annual production to determine per-piece expenses. This calculation guarantees you’re pricing jewelry to cover both materials and business operations effectively.

Base Price Formula Implementation and Multiplier Methods

You’ll calculate your base price by multiplying your combined material and packaging costs by four, then adding your hourly labor charges and a 10% overhead markup.

This method guarantees you’re covering all expenses while building in profit margins that support your business sustainability.

Don’t rely on simple doubling strategies that many artists use, as they typically fail to account for true costs and can lead to losses.

Material Cost Calculation

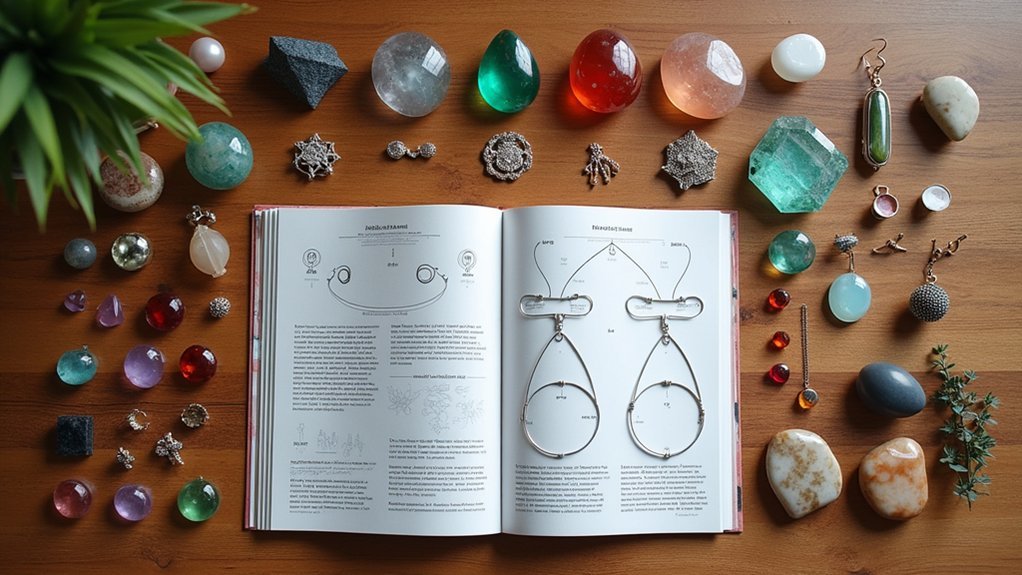

Three fundamental approaches exist for calculating material costs in jewelry making, each designed to guarantee profitability while maintaining competitive pricing.

You’ll need to track the actual cost of metals, gemstones, and findings used in each piece. Start by weighing precious metals and calculating current market prices, then add gemstone costs based on quality grades and sizes.

Don’t forget smaller components like wire, clasps, and settings.

Market fluctuations greatly impact your material costs, so you’ll want to update pricing regularly. Gold and silver prices change daily, affecting your bottom line.

Consider buying materials in bulk to reduce per-unit costs, but factor storage and insurance expenses.

Always document exact quantities used per piece, creating accurate cost records that’ll inform your final pricing decisions effectively.

Labor Rate Integration

Since material costs alone won’t cover your business expenses, integrating labor rates into your pricing structure becomes essential for sustainable profitability.

Calculate your hourly labor rate, then pro-rate it based on time spent creating each piece. For example, if you earn $20 hourly and spend 30 minutes on a jewelry piece, add $10 for labor costs.

The multiplier method offers another effective pricing approach. Multiply your total material and packaging costs by 2.5 to 4, which automatically covers labor and operational expenses.

Regardless of your chosen method, add 10% for overhead expenses like utilities and marketing.

Consistently review and adjust your labor rate integration strategy based on annual overheads and productive hours to maintain profitable pricing that sustains your business long-term.

Overhead Markup Application

When applying overhead markup to your jewelry pricing, the base price formula provides a systematic approach that guarantees all costs are covered.

You’ll multiply your combined materials and packaging costs by four, then add your pro-rated hourly labor rate plus 10% for overhead costs. This calculation establishes your absolute minimum selling price to prevent losses.

For instance, with $6 in supplies and $10 in labor for thirty minutes, you’d calculate:

($6 × 4) + $10 + 10% overhead = $37.40 base price.

Never sell below this threshold. You can adjust pricing upward based on your piece’s quality, uniqueness, and market demand.

Consider standard retail markups of 100% to 300% above your base price to guarantee healthy profit margins.

Packaging and Presentation Cost Integration

While many jewelry makers focus solely on material and labor costs, you’ll discover that packaging and presentation expenses play an essential role in your overall pricing strategy.

You should integrate packaging costs into your jewelry pricing formula by adding $1 to $2 for quality materials that enhance your piece’s presentation.

Consider your packaging type carefully—custom boxes or eco-friendly wraps greatly impact total costs and perceived value. Professional touches like branded tags or tissue paper elevate the customer experience and justify higher retail prices.

Don’t forget shipping materials, which add $3 to $5 to overall packaging expenses. Factor in padded envelopes or protective boxes for safe delivery.

Properly accounting for packaging guarantees every aspect, from production to customer delivery, is covered in your final pricing strategy.

Market Value Assessment and Competitive Price Research

Beyond calculating your production and packaging expenses, you’ll need to research what customers actually pay for similar jewelry pieces in your market.

Start by analyzing competitor shops that create handmade jewelry similar to yours. Study their pricing strategies, materials used, and target demographics to understand where your pieces fit competitively.

Your jewelry pricing formula should balance material cost, labor, and overhead while reflecting market realities. High-quality craftsmanship can justify premium pricing, but you must align with customer expectations and purchasing power.

Monitor current market trends and gather direct customer feedback about pricing perceptions.

This research helps you position your jewelry appropriately—ensuring you’re neither underpricing your work nor pricing yourself out of your target market’s reach.

Template Customization for Different Jewelry Types

Since different jewelry types require distinct materials, labor, and finishing processes, you’ll need to customize your cost template for each category you create.

Start by specifying material costs—precious metals for fine jewelry versus non-precious alternatives for costume pieces. Adjust labor time inputs based on design complexity, as intricate pieces demand more hours than simpler styles, directly impacting your labor costs.

Factor in varying packaging expenses since luxury items require premium presentation compared to everyday pieces. Include location-specific overhead percentages that reflect your operational scale and business expenses.

Don’t forget additional processing costs like electroplating, which vary greatly between jewelry types and substantially affect your final pricing calculations.

Profit Margin Analysis and Sustainability Planning

Understanding your true profit margin requires you to calculate every expense that goes into creating your jewelry pieces.

You’ll need to factor in materials, labor, overhead, and shipping costs to establish your baseline. Apply a markup formula that’s at least 2.5 times your material and packaging costs, then add your hourly labor rate plus 10% overhead.

Calculate materials, labor, overhead, and shipping costs, then apply at least 2.5x markup plus hourly labor rate and 10% overhead.

Monitor market trends and customer willingness to pay regularly, adjusting your prices to maintain competitiveness without sacrificing profitability.

Document customer feedback to guarantee your perceived value matches market expectations. This helps you refine both pricing strategies and product offerings.

Invest in ongoing education about pricing techniques and sustainability planning.

This continuous learning approach keeps your jewelry business financially healthy while adapting to changing market conditions.

Digital Tools and Spreadsheet Setup Guidelines

Precision becomes your competitive advantage when you leverage digital pricing tools and well-structured spreadsheets for jewelry cost calculations.

You’ll want to start with spreadsheet templates that include dedicated columns for material costs, labor hours, hourly rates, and overhead expenses. Google Sheets offers real-time collaboration features and automatic updates when material prices fluctuate, keeping your calculations current.

Your cost calculator should incorporate built-in formulas for profit margins and retail markups, streamlining your pricing strategy. These templates automate complex calculations, factoring in materials, labor, and overhead for accurate results.

Consider embedding cost calculators directly on your website to provide transparent pricing information to customers. This approach enhances trust while simplifying the purchasing process and demonstrating your professional approach to pricing handmade jewelry.

Cost Adjustment Factors for Complex Designs

Complex jewelry designs require strategic cost adjustments that go far beyond your standard spreadsheet calculations. You’ll need to factor in multiple variables that can dramatically impact your jewelry pricing structure.

| Cost Factor | Standard Design | Complex Design |

|---|---|---|

| Mold Costs | $30-50 single | $150-400 multiple |

| Material Premium | Base rate | 15-40% markup |

| Processing Time | Standard labor | 2-5x multiplier |

| Electroplating | Basic finish | Premium rhodium |

| Shipping Weight | Minimal impact | Significant cost |

Your intricate pieces demand premium materials like rare gemstones and high-quality metals, which fluctuate based on market demand. Processing costs increase substantially due to skilled crafting, detailed setting, and finishing requirements. Don’t overlook electroplating expenses—rhodium’s the costliest option for detailed finishes. Always include shipping and payment processing in your final calculations.

Price Testing Strategies and Customer Feedback Integration

While calculating complex design costs provides your baseline pricing structure, testing those prices in real market conditions reveals whether customers will actually pay what you’re asking.

You’ll need price testing strategies that gradually adjust prices on select jewelry items to gauge customer reactions and sales performance. Monitor which pieces sell well at higher prices versus those requiring discounts to move inventory.

Customer feedback integration comes through surveys and direct interactions, helping you understand price sensitivity and perceived value.

Use A/B testing by offering identical items at different prices across separate markets or platforms. This data-driven approach determines ideal pricing that maximizes both sales and profit margins while ensuring your prices reflect market demand and quality perceptions.

Template Maintenance and Regular Cost Review Processes

Once you’ve established your pricing through market testing and customer feedback, maintaining accurate cost templates becomes the foundation for sustained profitability.

You’ll need to schedule quarterly reviews to capture market fluctuations and guarantee your jewelry business remains profitable. Update material prices, labor rates, and overhead expenses immediately when changes occur.

Keep detailed records for each jewelry piece, including materials, labor, and packaging costs. This documentation makes pricing adjustments seamless when necessary.

Log supplier price changes and shipping cost variations, as these greatly impact your bottom line.

Use analytics tools to evaluate your pricing strategy’s effectiveness. Track sales performance and customer responses to identify when template maintenance is needed.

Regular cost reviews prevent profit erosion and keep your jewelry business competitive in changing markets.

Frequently Asked Questions

How Do You Figure Out How Much Something Costs to Make?

You’ll add up your material costs, calculate labor time at your hourly rate, include packaging expenses, then multiply by four and add ten percent for overhead costs.

How Much Does It Cost to Start Making Jewelry?

You’ll need $500 to $2,000 for initial materials, tools, and supplies. Add $200 to $500 annually for overhead like website hosting and marketing. Factor in your hourly wage for labor costs too.

How Do You Calculate Markup on Jewelry?

You’ll multiply your total material costs by 2-3 for retail markup. Include labor, overhead, packaging, and shipping in calculations. Research competitor prices to guarantee you’re competitive while maintaining profitability margins.

How Much Profit Should I Make on Handmade Jewelry?

You should aim for 60-80% profit margins on handmade jewelry. This guarantees you’re covering materials, labor, overhead costs, and business sustainability while remaining competitive in the market without undervaluing your craftsmanship.

In Summary

You’ve got the framework to build profitable jewelry pricing templates that’ll protect your margins and grow your business. Don’t let fear of pricing too high hold you back—you’re worth what you charge when you’ve calculated accurately. Start implementing these templates today, track your actual costs religiously, and adjust your pricing as you gather real data. Your success depends on pricing with confidence, not guesswork.

Leave a Reply