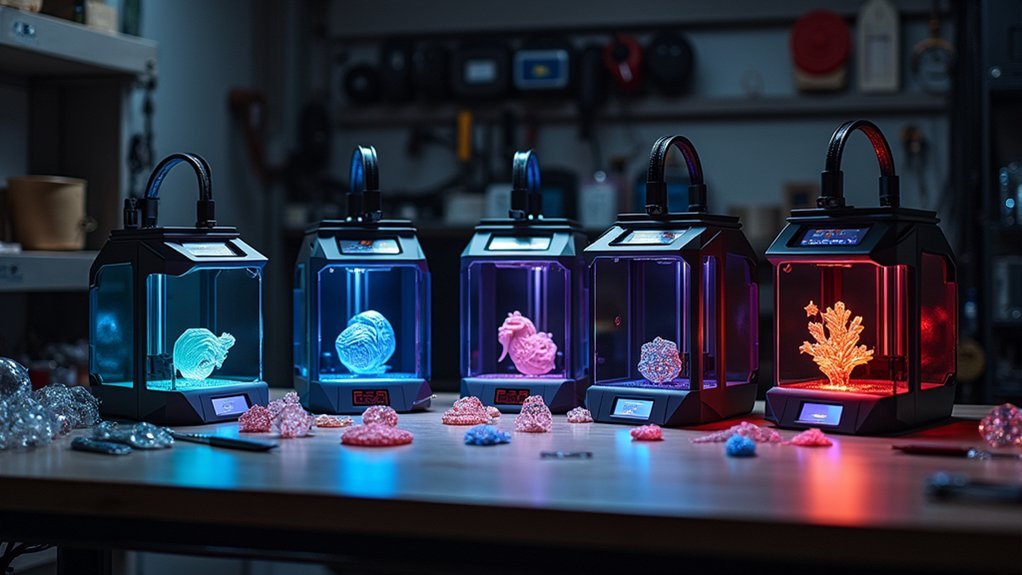

You’ll want to evaluate five standout printers for jewelry design: the Sonic Mini 8K offers 22-micron resolution under $700, while the Form 3+ SLA provides 25-micron precision with specialized castable resins. The B9 Core Series delivers production-ready workflows with 45-minute print times, and Asiga DLP printers combine speed with high-volume accuracy. The ProJet MJP creates direct casting models without support structures. Each option brings unique advantages that’ll transform your design process.

Sonic Mini 8K: Ultra-High Resolution for Intricate Details

When you’re crafting delicate jewelry pieces, the Sonic Mini 8K delivers exceptional precision with its 22-micron resolution—three times finer than a human hair strand.

This printer for jewelry produces stunning 8K prints with sharp details and minimal pixelation, dramatically outperforming 2K and 4K alternatives.

You’ll achieve consistent, flawless results that capture every intricate design element your jewelry demands. The printer’s blue cast resin X filigrees technology guarantees fine features are reproduced without artifacts, maintaining the integrity of your most detailed work.

Blue cast resin X filigrees technology ensures your most intricate jewelry details are captured flawlessly without any artifacts or imperfections.

At under $700, this printer offers exceptional value for small jewelry businesses.

You’ll find the print quality rivals much more expensive equipment, making it an intelligent investment that won’t strain your budget while delivering professional-grade results for your jewelry designs.

Form 3+ SLA Printer: Professional-Grade Precision and Material Versatility

While the Sonic Mini 8K excels at ultra-fine resolution, the Form 3+ SLA printer takes a different approach to jewelry excellence through its professional-grade engineering and material flexibility.

You’ll achieve stunning 25-micron layer resolution that captures every intricate detail in your jewelry designs with remarkable precision.

The Form 3+ utilizes Low Force Stereolithography technology, dramatically reducing print failures while delivering consistently smooth results.

You’ll appreciate its compatibility with specialized castable resins designed specifically for jewelry applications, enabling seamless shifts from prototype to production.

With a generous 145 x 145 x 175 mm build volume, you can print multiple pieces simultaneously, boosting your productivity considerably.

The intuitive interface and advanced software streamline your workflow, making this one of the top Printers for Jewelry professionals who demand reliability and versatility.

B9 Core Series: Production-Ready Digital Workflow Solutions

Speed transforms everything in jewelry production, and the B9 Core Series delivers exactly that advantage with its production-ready digital workflow solutions. When you’re looking for the best 3D printer that’ll revolutionize your workflow, this platform’s designed for precision and reliability at mass production costs.

| Feature | Specification | Benefit |

|---|---|---|

| Print Time | 45 minutes | Rapid castable models |

| Setup Time | 15 minutes | Quick prototyping |

| Price | $8,495 | Cost-effective solution |

You’ll create custom prints with just five button pushes for master molds, while the intelligent software streamlines preparation and monitoring. The B9 Core XL Jewelers Edition offers large build volume with industry-leading resolution, perfect for intricate designs. For jewelry manufacturers seeking operational efficiency, this system reduces wait times and improves profitability considerably.

Asiga DLP Printers: Speed and Accuracy for High-Volume Production

Although high-volume jewelry production demands both speed and precision, Asiga DLP printers deliver exactly this combination through their advanced digital light processing technology.

You’ll achieve faster printing speeds compared to traditional SLA systems while maintaining exceptional dimensional accuracy for intricate designs. These printers excel at producing detailed pieces that require precision, making them ideal when you’re creating complex jewelry components.

You can print various materials, expanding your design capabilities and exploring diverse applications for your jewelry business.

While the initial investment runs higher, you’ll realize significant cost savings through improved efficiency and increased output. The reliability and productivity of Asiga printers have made them preferred choices across jewelry and dental sectors, ensuring your production workflow remains consistent and dependable.

ProJet MJP Wax Printer: Direct Casting Models Without Support Structures

When traditional lost wax casting meets modern 3D printing technology, the ProJet MJP Wax Printer bridges this gap seamlessly by producing highly detailed models that integrate directly into your existing casting workflow.

You’ll eliminate support structures entirely while achieving exceptional print quality that’s among the best available on the market.

The unique wax material creates highly castable models with intricate designs and superior surface finish.

You’ll experience enhanced productivity through rapid prototyping and customization capabilities, dramatically reducing fulfillment times for jewelry orders.

This printer excels at complex jewelry applications where precision matters most.

For jewelers seeking to blend modern technology with traditional techniques, the ProJet MJP provides a reliable solution for bespoke jewelry creation without compromising quality or workflow efficiency.

Frequently Asked Questions

Can You Print Jewellery With a 3D Printer?

Yes, you can print jewelry with a 3D printer using SLA, DLP, or LCD technologies. You’ll achieve incredible detail with resolutions like 22 microns, enabling rapid prototyping and customization while reducing production times considerably.

What Is the 45 Degree Rule for 3D Printing?

You should avoid overhangs exceeding 45 degrees from vertical when designing 3D models. This rule prevents sagging and print failures by ensuring your printer can successfully create features without requiring additional support structures underneath.

What Is the Most Profitable 3D Printing Business?

You’ll find jewelry 3D printing most profitable, especially rapid prototyping and custom pieces. Companies like Vowsmith deliver wedding rings in 72 hours, maximizing profits through reduced waste and personalized designs.

What 3D Printer Does Jay Leno Use?

You’ll find Jay Leno uses the B9 Core Series 3D printers for his automotive restoration projects. He’s chosen these for their precision and speed when creating custom parts for his vintage car collection.

In Summary

You’ve now seen five exceptional 3D printers that’ll transform your jewelry design process. Whether you’re prioritizing ultra-fine detail with the Sonic Mini 8K, seeking professional versatility with the Form 3+, or need production-ready solutions like the B9 Core Series, there’s a printer that’ll match your specific requirements. Consider your budget, production volume, and detail needs when making your final decision. You’ll find these printers will greatly enhance your creative capabilities.

Leave a Reply