You’ll need nine essential precision metal tools for professional jewelry making: digital calipers for accurate measurements up to 0.01mm, metal rulers for symmetrical marking and layout work, dividers and compasses for creating perfect circles and arcs, ring mandrels for exact sizing and shaping, wire gauges to measure metal thickness using the AWG system, proportional dividers for scaling designs, depth gauges for stone settings, micrometers for ultra-fine 0.001mm precision, and digital measuring devices for enhanced workflow efficiency. These tools transform your craftsmanship from amateur to professional-grade results.

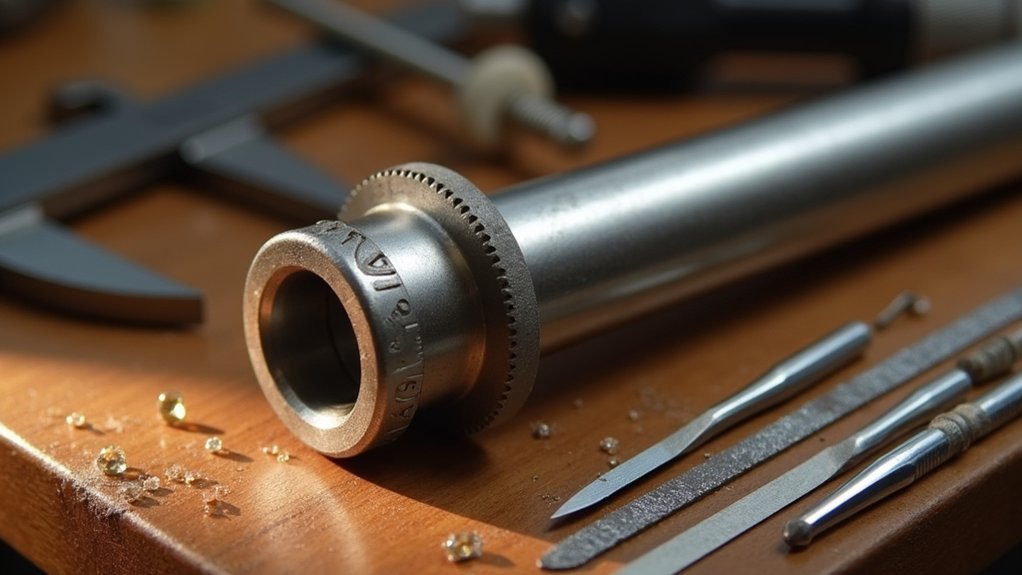

Calipers: Essential for Precise Measurements in Jewelry Making

When you’re crafting jewelry, you’ll quickly discover that calipers are essential for achieving the precision your work demands.

These jewelry making tools enable you to obtain precise measurements of metal sheets, wire thickness, and gemstone dimensions, ensuring accuracy in every design element.

You’ll find two main types available: digital calipers offer easy reading, while vernier calipers provide traditional analog measurement.

High-quality models typically measure up to 6 inches and handle both internal and external dimensions, critical for creating well-fitted pieces.

Look for calipers with locking mechanisms that maintain measurements while transferring them to your work.

Remember to calibrate and maintain your calipers regularly – consistent, reliable measurements are fundamental for professional results in your jewelry making endeavors.

Metal Rulers and Scales: Foundation Tools for Accurate Marking

You’ll need reliable metal rulers and scales as your foundation tools for creating precise measurements and clean marks on jewelry materials.

Your choice of ruler type directly impacts measurement accuracy, with graphing rulers offering superior visibility for detailed work.

When selecting marking tools to pair with your rulers, you’re ensuring every line and measurement contributes to professional-quality results.

Essential Ruler Types

Three fundamental types of metal rulers form the backbone of precise jewelry making: standard steel rulers, graphing rulers, and dual-measurement scales.

Standard steel rulers provide the durability you need for consistent measurements, ensuring your designs maintain perfect symmetry. Their rigid construction won’t bend or warp during use, making them essential precision tools for professional work.

Graphing rulers offer superior visibility with clear markings that help you align and visualize complex designs more effectively. You’ll find these metal rulers particularly useful when creating intricate patterns or geometric jewelry pieces.

Dual-measurement scales featuring both metric and imperial units give you versatility across different project requirements. These measuring tools accommodate industry standards while complementing other precision instruments like calipers and dividers for enhanced accuracy in cutting and shaping materials.

Scale Measurement Accuracy

Although even the finest metal ruler becomes useless without proper calibration, achieving scale measurement accuracy requires understanding how environmental factors and manufacturing tolerances affect your readings.

Temperature fluctuations can cause metal rulers to expand or contract, altering measurements by fractions that matter when creating precise jewelry components.

You’ll need precision scales that maintain accuracy across different weights and conditions. Digital scales offer consistent readings, while balance scales provide reliable performance without electronic dependencies.

Regular calibration guarantees your tools deliver professional results. When selecting precision scales, consider resolution requirements for your specific projects.

Gemstone weighing demands different accuracy levels than bulk metal measurements. Quality metal rulers paired with properly maintained scales create the measurement foundation essential for exceptional jewelry craftsmanship.

Marking Tool Selection

Accurate measurements form the foundation for selecting the right marking tools that’ll transform your jewelry designs from concept to reality. Metal rulers deliver essential accuracy for creating symmetrical designs and consistent sizing. You’ll want graphing rulers for enhanced visibility during the marking process, helping you visualize your designs clearly.

| Tool Type | Primary Function | Key Benefit |

|---|---|---|

| Metal Rulers | Linear measurements | Symmetrical designs |

| Dividers | Transfer measurements | Create precise arcs |

| Center Punches | Mark drill points | Exact hole locations |

Dividers excel at transferring accurate measurements and creating arcs with precision. Center punches create indentations for drilling, providing exact locations that enhance overall accuracy. Investing in high-quality marking tools greatly improves your jewelry’s precision and professional quality, making these foundational instruments indispensable for serious craftspeople.

Dividers and Compasses: Creating Perfect Circles and Arcs

Two fundamental tools stand at the heart of precision metalwork: dividers and compasses. These essential instruments enable you to accurately measure and transfer distances while creating perfect circles and arcs in your jewelry projects.

Dividers excel at transferring measurements between pieces, ensuring consistent spacing and proportions throughout your work.

Dividers ensure precise measurement transfer and consistent spacing, eliminating guesswork from your metalworking projects.

Compasses, typically equipped with pencils or scribes, let you draw flawless circles directly onto metal surfaces. Both tools feature adjustable mechanisms that accommodate various radii, giving you the flexibility to create different shapes and sizes.

When you invest in high-quality versions with smooth, precise mechanisms, you’ll achieve clean markings that minimize design errors. Using these tools alongside other measuring instruments enhances your overall precision, delivering professional-grade results.

Ring Mandrels: Sizing and Shaping Rings to Exact Specifications

When you’re creating or resizing rings, you’ll need a reliable ring mandrel to achieve exact specifications every time.

Different mandrel types—from basic steel versions to specialized oval or bracelet mandrels—offer unique advantages depending on your specific shaping requirements.

You’ll master precise sizing techniques by understanding how to properly position the ring, apply consistent pressure with your mallet, and read the graduated markings for accurate measurements.

Ring Mandrel Types

Three primary materials define the ring mandrel landscape, each offering distinct advantages for sizing and shaping rings to exact specifications.

A steel ring mandrel delivers unmatched durability and precision, featuring graduated size markings that guarantee accurate measurements for professional-grade work. You’ll find it essential for heavy-duty projects requiring exact specifications.

A wood ring mandrel offers affordability and lighter weight, making it perfect for initial shaping and sizing tasks. While it won’t match steel’s longevity, it’s ideal for beginners and lighter applications.

Plastic mandrels serve lightweight projects effectively and can accommodate custom size markings. However, they’re less suitable for intensive use.

Most ring mandrels span US sizes 1-12, covering standard finger measurements. Pair your chosen mandrel with a ring sizer gauge to assure precise sizing before finalizing designs.

Precise Sizing Techniques

While selecting the right mandrel sets the foundation, mastering precise sizing techniques transforms your jewelry work from adequate to exceptional.

Your steel ring mandrel provides standard sizes from 1 to 15, enabling accurate measurements for perfect fits. The tapered design maintains circular integrity while you expand or reduce ring sizes.

Use a mallet to gently tap rings onto the mandrel, stretching or compressing metal without compromising structural integrity.

Mark your mandrel with size measurements to enhance precision and streamline workflow when sizing multiple pieces. Pair your mandrel with calipers to measure inner diameters before shaping – this combination dramatically improves accuracy.

These techniques guarantee consistent, professional results while preventing costly mistakes that damage valuable metals and gemstones.

Wire Gauges: Measuring Metal Thickness With Professional Accuracy

Understanding wire gauge measurements forms the foundation of precision jewelry making, directly impacting both the structural integrity and aesthetic appeal of your finished pieces.

The American Wire Gauge (AWG) system uses inverse numbering—higher numbers mean thinner wires. You’ll find 24-gauge wire (0.0201 inches) perfect for larger beads and structural components, while 30-gauge wire (0.0100 inches) excels in delicate work.

Remember: higher AWG numbers mean thinner wire—24-gauge for structure, 30-gauge for delicate details.

Most jewelers work within the 20-30 gauge range, balancing strength with flexibility. Your wire choice determines whether components like jump rings will function properly and withstand daily wear.

Thicker gauges provide durability for clasps and findings, while thinner options allow intricate wire-wrapping techniques. Mastering wire gauges guarantees your designs achieve professional accuracy, with each element fitting precisely and performing its intended function reliably.

Center Punches: Marking Precise Points for Drilling and Setting

When you’re marking drilling points on metal for jewelry work, you’ll need a center punch to create precise indentations that guide your drill bit exactly where you want it.

This essential tool prevents your drill from wandering across the metal surface, ensuring you’ll achieve the accurate holes required for stone settings and decorative elements.

You’ll find that proper center punch technique involves positioning the hardened steel point at your mark and delivering a firm, controlled strike to create the perfect starting dimple.

Accurate Point Marking

Since accurate drilling forms the foundation of professional jewelry work, center punches serve as your first line of defense against imprecise holes and misaligned settings.

These essential tools create small dimples that prevent drill bits from wandering across metal surfaces, ensuring your holes land exactly where intended.

You’ll find center punches available in various sizes and styles, allowing you to match the tool to your specific metal thickness and type.

When using them, apply controlled pressure to create clear marks without damaging your workpiece. The technique requires precision—too little pressure won’t create an adequate guide, while too much can distort thin metals.

Investing in high-quality center punches greatly improves your accuracy, reduces material waste, and elevates your overall craftsmanship standards considerably.

Drilling Preparation Techniques

Before you begin any drilling operation, proper preparation with center punches greatly reduces errors and material waste.

These essential tools feature hardened steel tips that create small indentations on metal surfaces, preventing drill bits from wandering during operation. The precise marking guarantees your holes end up exactly where you intended them.

When using center punches, apply firm, controlled pressure to avoid damaging surrounding areas. Always strike with a hammer or mallet to generate sufficient force for clear, defined marks.

This technique considerably reduces splitting and cracking risks, particularly important when working with delicate jewelry materials.

The stable starting points created by center punches make the entire drilling process more predictable and professional. Your finished pieces will show improved accuracy and cleaner hole placement.

Ring Sizers: Determining Accurate Finger Measurements

Every successful ring fitting begins with precise finger measurements, and ring sizers serve as your most reliable tools for achieving this accuracy. You’ll find these instruments in various forms, each designed to capture accurate measurements for different finger sizes.

| Tool Type | Material | Best Use Case |

|---|---|---|

| Plastic Bands | Plastic | Quick customer sizing |

| Metal Mandrels | Steel/Aluminum | Professional ring fitting |

| Digital Gauges | Electronic | Precision measurements |

| Ring Mandrels | Tapered Metal | Existing ring sizing |

You should take multiple measurements throughout the day since fingers fluctuate due to temperature and swelling. Digital ring sizers offer advanced precision by capturing even slight size differences electronically. The standard U.S. scale ranges from size 1 to 16, with half and quarter increments available for ideal fitting precision.

Proportional Dividers: Scaling Designs to Different Sizes

Proportional dividers transform your original jewelry designs into perfectly scaled versions across multiple sizes while preserving every detail’s intended relationship.

These essential tools feature two arms connected by a pivot point, letting you transfer measurements from your model to larger or smaller scales without distorting proportions.

You’ll find these dividers particularly valuable when creating pieces that must fit specific dimensions, like rings or pendants. They help you maintain aesthetic balance across different sizes while ensuring design consistency.

Key benefits of proportional dividers include:

- Accurate scaling – Increase or decrease dimensions without losing design integrity

- Time efficiency – Quickly transfer measurements between different project scales

- Durable construction – Metal construction provides precision for repetitive scaling designs work

These tools eliminate guesswork from your scaling process, delivering professional results every time.

Depth Gauges: Measuring Stone Seats and Bezels Accurately

Precision becomes critical when creating stone settings that showcase gemstones at their finest.

You’ll need depth gauges to accurately measure stone seats and bezels, ensuring your gems sit perfectly within each design. These essential jewelry-making tools feature serrated edges or probes that let you measure setting depths without damaging metal or stones.

Quality depth gauges display clear markings in millimeters or inches, helping you achieve consistent measurements across projects. You’ll prevent costly mistakes like selecting stones that are too thick or thin for your intended settings.

For thorough measuring, you can combine depth gauges with calipers, especially when working with intricate designs or multiple stones. This precision tool becomes indispensable for professional-quality stone setting work.

Micrometers: Ultra-Precise Measurements for Fine Jewelry Work

While depth gauges handle stone setting measurements effectively, micrometers take your precision capabilities to an entirely new level.

These essential tools deliver measurements accurate to 0.001 mm (1 micron), making them indispensable for fine jewelry work where every detail matters.

In fine jewelry craftsmanship, precision down to 1 micron separates amateur work from professional-grade excellence.

You’ll find micrometers feature screw mechanisms for fine adjustments, perfect for measuring metal sheets and wires in intricate designs.

Their locking mechanisms maintain set measurements during repetitive tasks, ensuring consistent precision throughout your work.

Key micrometer types for jewelry making:

- Outside micrometers – measure external dimensions of components

- Inside micrometers – handle internal measurements and hollow spaces

- Calibrated models – require regular calibration for maintained accuracy

Professional jewelers rely on micrometers because they deliver the ultra-precise measurements essential for high-quality craftsmanship and perfect component fitting.

Digital Measuring Tools: Modern Technology for Enhanced Precision

Modern digital measuring tools revolutionize jewelry making by combining traditional precision with advanced technology features that streamline your workflow.

Digital calipers deliver measurements accurate to 0.01mm, ensuring exact dimensions for every component you create. You’ll appreciate how digital micrometers achieve even finer precision at 0.001mm, perfect for detailed metalwork requiring ultra-precise thickness measurements.

Digital angle finders eliminate guesswork when creating complex cuts and joins, giving you perfect alignments every time. These tools often include conversion functions, letting you switch between metric and imperial units instantly for international projects.

Laser measuring tools offer non-contact options, protecting delicate surfaces while measuring complex shapes. This technology combination enhances your precision while reducing measurement time considerably.

Frequently Asked Questions

What Tools Do Professional Jewelers Use?

You’ll use jeweler’s saws with precision blades, soldering equipment like acetylene torches, specialized pliers for wire manipulation, flexshafts for versatile tasks, and essential safety gear including goggles and respirators.

What Equipment Do You Need to Be a Jeweler?

You’ll need a sturdy workbench, high-quality pliers, jeweler’s saw with blades, precision measuring tools like calipers, and essential safety equipment including goggles and masks for professional jewelry-making work.

What Do I Need to Make Metal Jewelry?

You’ll need a jeweler’s saw, quality pliers, and soldering equipment for joining metals. Don’t forget a sturdy workbench, measuring tools like calipers, safety goggles, and various files for finishing your pieces professionally.

What Tools Do I Need to Make Jewellery?

You’ll need essential pliers like flat-nose, round-nose, and chain-nose for wire work. Add flush cutters, a jeweler’s saw, measuring tools like calipers, and safety equipment including goggles and dust masks.

In Summary

You’ll find that investing in quality precision metal tools transforms your jewelry-making capabilities. These instruments aren’t just accessories—they’re essential partners in creating professional-grade pieces. Whether you’re measuring wire thickness or scaling intricate designs, having the right tools guarantees your work meets exacting standards. Don’t compromise on precision; your craftsmanship depends on accurate measurements. With these tools in your workshop, you’ll consistently produce jewelry that reflects true professional quality and attention to detail.

Leave a Reply