You’ll achieve perfect soldering when your metal surfaces are completely clean and properly prepared. Remove all dirt, grease, oils, and oxidation using steel wool, emery cloth, or chemical cleaners like isopropyl alcohol. Apply appropriate flux to break down remaining oxides and prevent new oxidation from forming. Abrading creates a dull, matte surface that increases adhesion area for stronger bonds. Maintain proper iron temperature between 600-750°F and avoid touching cleaned surfaces with bare hands to preserve preparation quality and discover advanced techniques.

Understanding Metal Surface Contaminants and Oxidation

Before you can create a strong solder joint, you must understand that metal surfaces naturally accumulate contaminants that act as barriers to proper adhesion.

These contaminants include dirt, grease, and oils that prevent effective solder flow during proper soldering operations.

Oxidation presents the most significant challenge, forming an invisible layer that blocks solder from bonding with the underlying metal.

Oxidation creates an invisible barrier between solder and metal, preventing the strong bonds essential for reliable electrical connections.

You’ll need abrasives like steel wool or emery cloth to remove this oxidation layer effectively.

Don’t overlook the importance of cleaning hands before handling components, as oils from your skin transfer to metal surfaces.

When dealing with stubborn oxidation, additional flux helps improve solder adhesion by breaking down remaining barriers and promoting clean, reliable connections.

Essential Cleaning Methods and Solutions for Metal Preparation

Now that you understand what creates barriers to proper solder adhesion, you’ll need specific methods to remove these contaminants effectively.

Getting metal surfaces thoroughly cleaned requires systematic approaches that target different types of contamination.

Your cleaning arsenal should include these essential methods:

- Mechanical cleaning – Use steel wool, files, or emery cloth to abrade surfaces and remove stubborn oxides while creating texture for better solder bonding.

- Chemical cleaning – Apply isopropyl alcohol to dissolve grease and oils, ensuring contaminant-free metal surfaces.

- Flux application – Choose acid-core solder for heavy oxidation or rosin-core solder for general electrical work to enhance soldering effectiveness.

After cleaning, avoid touching prepared surfaces with bare hands.

The flux will activate during heating, chemically removing remaining oxides and promoting proper solder flow for strong, reliable joints.

The Critical Role of Flux in Metal Readiness

While mechanical and chemical cleaning remove most contaminants, flux serves as your final line of defense against oxidation and residual impurities that can sabotage your solder joints.

This cleaning agent breaks down remaining oxides and prevents new oxidation during heating, ensuring proper adherence between metals and solder. You’ll need to select flux that’s compatible with your specific solder and metals—rosin-based for electronics or acid-based for plumbing applications.

The right flux dramatically improves solder flow, creating smooth, professional joints.

However, don’t skip the cleanup phase. You must remove residual flux with isopropyl alcohol after soldering to prevent long-term corrosion.

This final step guarantees excellent results and lasting solder joint reliability.

Proper Surface Abrading Techniques for Optimal Solder Flow

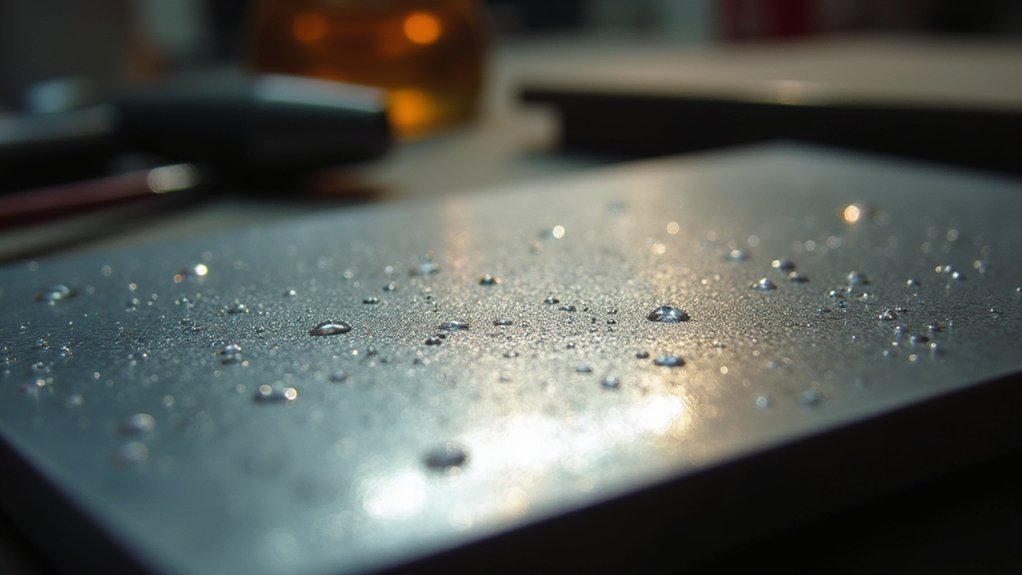

Even with chemical cleaning and flux preparation, you’ll need to mechanically abrade metal surfaces to achieve the dull, clean finish that’s essential for strong solder bonds.

Mechanical abrasion remains crucial for proper solder joint preparation even after chemical cleaning and flux application.

This proper surface preparation dramatically increases surface area for ideal adhesion.

Choose the right abrasive techniques for your project:

- Steel wool or cleaning pad – Remove oxidation and create uniform texture across larger metal sections

- Emery cloth – Provides controlled abrading for precision work and delicate components

- File or knife scraping – Expose fresh metal on wires and small surfaces

You’re aiming for a dull, matte appearance rather than shiny metal.

Once you’ve achieved good soldering surface preparation, apply flux and solder immediately.

Never touch the abraded area with bare hands, as skin oils contaminate the prepared surface and compromise joint strength.

Temperature and Timing Requirements for Clean Metal Surfaces

Once you’ve properly cleaned and abraded your metal surfaces, controlling temperature and timing becomes critical for achieving strong, reliable solder joints.

Set your soldering iron between 600°F and 750°F for effective soldering on clean metal surfaces. Apply heat to the solder joint for no more than six seconds to prevent thermal degradation of sensitive components.

If your connections require longer than six seconds, increase your iron’s temperature by 10-15°F rather than extending timing. Use additional flux to improve solder flow, especially on challenging surfaces, as it prevents oxidation during heating.

Proper timing and temperature control guarantee your clean metal surfaces receive ideal heat distribution, creating durable joints without component damage.

Frequently Asked Questions

How to Prep Metal for Soldering?

You’ll clean metal surfaces with steel wool or emery cloth to remove dirt and oxides. Scrape and tin wires beforehand. Apply flux for better flow. Chip away coatings and guarantee snug fitting between pieces.

What Is the Golden Rule of Soldering?

You’ll achieve perfect solder joints by following the golden rule: guarantee all metal surfaces are completely clean and free of dirt, grease, and oxidation before applying any solder.

What Is the Secret to Good Soldering?

You’ll achieve excellent results by keeping surfaces spotlessly clean, using proper flux, maintaining ideal temperature between 600-750°F, and ensuring tight-fitting joints. Clean metal and correct heat are absolutely essential for strong connections.

How Do You Ensure Proper Soldering Work?

You’ll achieve proper soldering by cleaning surfaces thoroughly, applying flux, maintaining tight joint fits, using correct temperatures between 600-750°F, and tinning your iron tip plus workpieces beforehand.

In Summary

You’ll achieve perfect soldering when you’ve properly cleaned your metal surfaces, removed all oxidation and contaminants, and applied the right flux. Don’t skip abrading techniques that create ideal surface texture for solder flow. Remember that temperature control and timing are essential – you can’t rush the process. When you’ve mastered these fundamentals, you’ll consistently produce strong, reliable solder joints that’ll stand the test of time.

Leave a Reply