Mokume Gane is a Japanese metalworking technique that fuses multiple colored metals together to create wood grain-like patterns. Dating back to 17th century sword embellishments, it combines metals like copper, silver, and gold through careful heating and pressure. You’ll find this distinctive art form in contemporary jewelry, particularly wedding bands and statement pieces. The process requires precise temperature control and compatible metals with similar melting points. Discover how this ancient craft transforms ordinary metals into extraordinary wearable art.

The Ancient Japanese Art of Mixed Metal Lamination

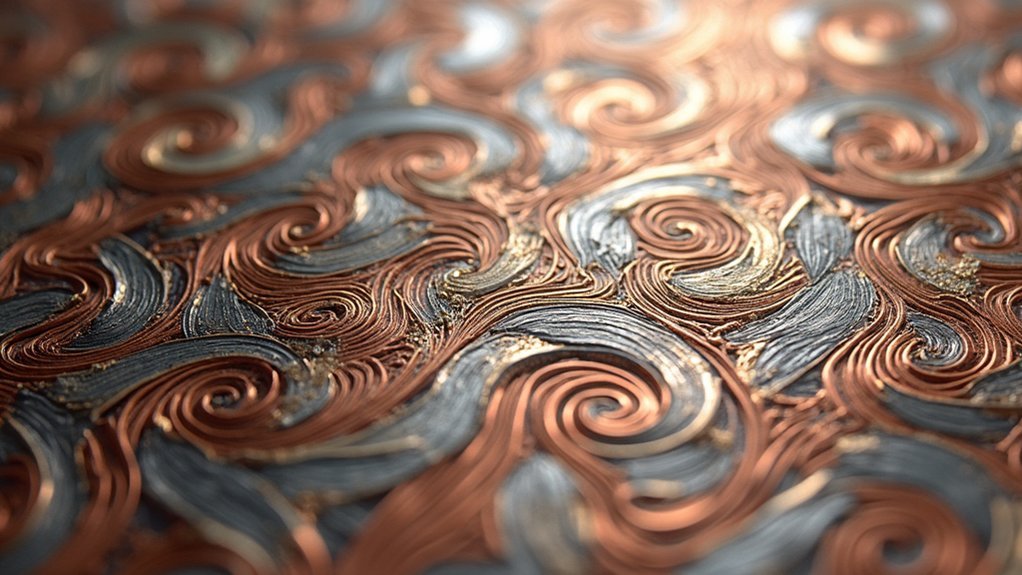

The enchanting technique of mokume gane emerged in 17th century Japan as master metalworkers developed methods to fuse different colored metals into striking patterns resembling wood grain.

Originally created for samurai sword embellishments, this sophisticated craft allowed artisans to produce distinctive visual effects through careful lamination of precious metals like copper, silver, and gold.

The Mokume Gane process requires exceptional skill and precision.

You’ll find that successful execution demands intimate knowledge of each metal’s properties and behavior under heat.

Artisans must apply precise temperature and pressure to bond the layers without melting them completely.

Through strategic twisting, carving, and forging of these fused layers, craftspeople create organic, flowing patterns that display remarkable depth and color contrast—a reflection of Japan’s enduring metalworking tradition.

Essential Metals and Materials for Mokume Gane

When creating mixed metal Mokume Gane, you’ll need to carefully select metals like copper, silver, and gold that complement each other visually while meeting essential compatibility requirements.

Your chosen metals must have similar melting points to fuse properly during the layering process without one metal liquefying before another.

Consider how the contrasting colors will interact in your final piece, as the warm tones of copper, brightness of silver, and richness of gold create the distinctive patterns that make this technique so enchanting.

Metal Selection Fundamentals

Selecting appropriate metals forms the foundation of successful Mokume Gane work, as your ability to create stunning patterns depends entirely on how well your chosen materials interact.

When planning your metal combinations, you’ll need to take into account compatibility of melting points—metals that fuse at similar temperatures will bond properly without compromising structural integrity.

Popular choices include precious metals like yellow, red, and white gold paired with sterling silver, each contributing distinct coloration to your design. Copper and bronze can also add dramatic contrast when incorporated thoughtfully.

You’ll find that understanding each metal’s oxidation properties and heat reactivity is essential for achieving those signature marbled effects through twisting, carving, and forging techniques.

The visual impact of your Mokume Gane pieces ultimately relies on your strategic selection of metals with complementary characteristics.

Compatibility Requirements

Successful Mokume Gane creation hinges on the compatibility between your chosen metals, as even slight mismatches can lead to failed fusion or structural weaknesses.

When working with Mokume Gane, you’ll need to select metals with similar melting points to guarantee proper bonding without any layers liquefying completely during the heating process.

- Precious metal combinations like yellow gold, red gold, white gold, and sterling silver create striking visual contrasts while maintaining workability.

- Surface preparation is critical—remove all oxides and contaminants before bonding to guarantee strong layer adhesion.

- Consider each metal’s malleability and oxidation behavior when planning your Mokume pattern development.

Understanding these compatibility factors allows you to create durable, visually stunning Mokume Gane pieces while avoiding common technical pitfalls that can compromise your work’s structural integrity.

Contrasting Color Considerations

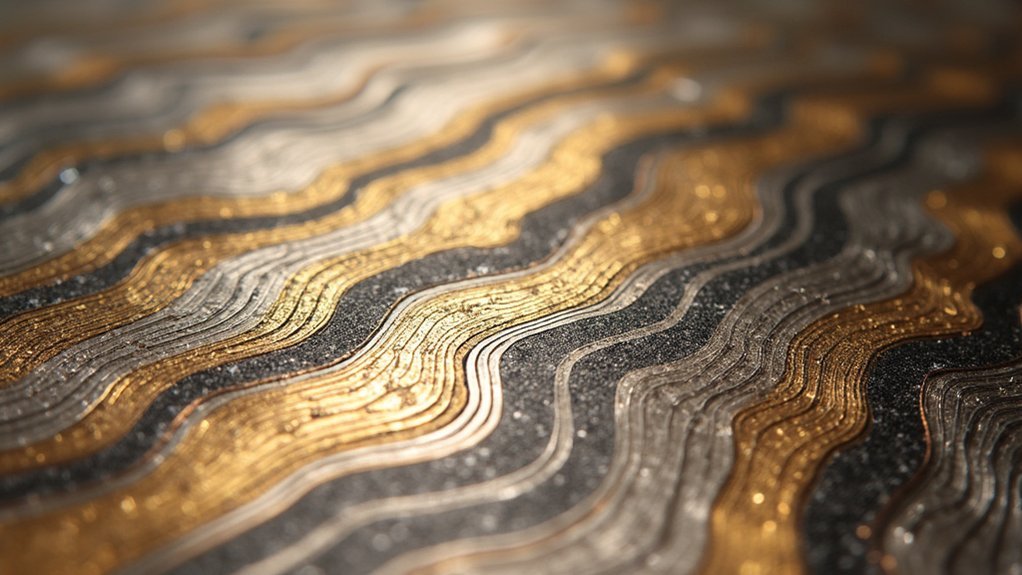

The visual impact of Mokume Gane largely depends on your metal selection, with contrasting colors creating the distinctive wood-grain patterns that define this ancient technique.

When designing your piece, consider how different metals will interact visually. Copper paired with silver or gold produces vibrant contrasts, while various gold alloys—yellow, red, and white—offer subtle yet distinctive variations.

The beauty of working with contrasting metals lies in how they respond differently to patination, enhancing the dimensional quality of your finished work.

Sterling silver creates bright highlights against warmer metals like bronze, while different karat golds introduce sophisticated color shifts.

You’ll need to balance aesthetic considerations with compatibility requirements, as your chosen metals must have similar melting points to fuse properly without compromising the structural integrity of your layered creation.

Studio Setup and Safety Considerations

You’ll need proper ventilation in your studio to safely draw away toxic fumes released when heating different metals in your mokume gane work.

Organize your tools in dedicated stations with hammers, files, and soldering equipment arranged by function and frequency of use for efficient workflow.

Store your copper, silver, and other metal sheets in flat, dry containers away from chemicals to prevent tarnishing and guarantee they’re ready when inspiration strikes.

Ventilation Requirements

Because working with mixed metals for Mokume Gane involves intense heating processes, proper ventilation stands as a non-negotiable safety requirement in your studio setup.

You’ll need to create airflow that draws fumes away from your breathing zone and expels them outside. When designing your workspace, guarantee windows can open or install exhaust fans that maintain constant fresh air circulation.

- Install a dedicated fume extraction system positioned near your soldering station to capture toxic vapors directly at their source.

- Set up your heating and fusing processes in a designated area with optimized ventilation requirements.

- Mount a carbon monoxide detector in your studio to monitor air quality and alert you to dangerous conditions.

Don’t compromise on ventilation requirements—your long-term health depends on proper ventilation during every Mokume Gane session.

Tool Organization

Safety systems like proper ventilation go hand-in-hand with thoughtful tool organization when creating a functional Mokume Gane workspace.

Set up distinct zones for each step of your process—metal preparation, layering, fusing, and shaping—to prevent cross-contamination between different metals and maintain workflow efficiency.

Store your tools and materials in clearly labeled containers, making everything from metal sheets to sculpting implements easily accessible during projects.

Establish a dedicated cleaning area to keep your workspace free of metal shavings and dust that could compromise your work.

Don’t forget to implement safety protocols alongside your tool organization system.

Keep a fire extinguisher and first-aid kit within reach to address potential accidents when working with heated metals.

Well-organized tools not only improve efficiency but enhance safety too.

Metal Storage Solutions

While creating beautiful Mokume Gane requires artistic skill, proper metal storage forms the foundation of both quality work and studio safety. Your mixed metals need protection from environmental factors that can compromise their integrity.

Store precious metals in anti-tarnish bags or boxes to prevent oxidation, which can affect bonding quality during the Mokume Gane process.

- Organize your mixed metals by type and size in clearly labeled containers for efficient workflow and quick material selection.

- Keep all metals in a cool, dry environment to prevent unwanted corrosion that can ruin carefully prepared metal stacks.

- Consider a magnetic storage system for smaller metal pieces and tools, keeping your workspace uncluttered and safer.

Proper storage not only extends the life of your materials but also enhances your studio’s efficiency and safety.

Preparing Your Metal Layers for Fusion

Successful mokume gane begins with proper metal preparation, as the quality of your fusion directly depends on how well you select and prepare your layers.

Start by choosing compatible metals with similar melting points—copper, silver, gold, and bronze work well for creating distinctive mokume patterns.

Metal selection is the foundation of mokume gane—choose companions with similar melting points for truly distinctive patterning.

Cut your selected sheets into equal sizes, then thoroughly clean each surface with fine abrasives or solvents to remove oxides and impurities. This cleaning step is essential for achieving strong bonds between layers.

Stack your metals in an alternating pattern, maintaining uniform thickness throughout.

Apply flux to prevent oxidation during heating, which guarantees cleaner fusion.

Finally, secure your stack with clamps to maintain perfect alignment during the heating process—any movement could compromise the beautiful layered effect you’re working to achieve.

Bonding Techniques for Mixed Metals

Three essential factors govern the mokume gane bonding process: heat, pressure, and precision timing.

When working with mixed metals, you’ll need to verify your chosen materials have compatible melting points. Apply flux liberally to prevent oxidation and create clean bonds between your metal layers.

Securely clamp your stacked layers before heating to maintain proper alignment throughout the fusion process. You’ll achieve stronger bonding by applying consistent pressure—either through traditional hand-hammering or using a mechanical press.

After successful fusion, roll and forge your billet to the desired thickness for further patterning.

- Use tight clamping techniques to prevent layer separation during heating

- Monitor temperature carefully to reach fusion without melting your metals

- Apply even pressure across the entire billet for consistent bonding

Creating Distinctive Wood Grain Patterns

Once your metal layers have successfully bonded, you’ll begin the artistic journey of creating wood grain patterns that give mokume gane its distinctive beauty. The manipulation of these fused layers is where mixed metal Mokume Gane transforms from simple metal sheets into stunning organic designs.

| Pattern Type | Technique | Result |

|---|---|---|

| Raindrop | Punching and forging | Circular patterns resembling raindrops |

| Ladder | Linear cutting and folding | Parallel lines with contrasting metals |

| Wood Grain | Twisting and carving | Natural, flowing wood-like patterns |

You’ll need to selectively cut, twist, and forge your metal billet to reveal the contrasting layers beneath. Each decision you make during this process affects how the final pattern emerges. Patination techniques can further enhance the visual contrast between your chosen metals, bringing out the depth of your design.

Tools and Equipment for Pattern Development

To create enchanting Mokume Gane patterns, you’ll need specialized tools like rolling mills, chisels, and texturing hammers that help manipulate the metal layers into distinctive designs.

Your heating equipment, including a torch or kiln, must precisely control temperature to successfully fuse the metal layers without completely melting them.

Don’t forget essential safety gear such as heat-resistant gloves and protective eyewear, which protect you from burns, sharp edges, and metal particles throughout the pattern development process.

Specialized Pattern-Making Tools

Creating intricate Mokume Gane patterns requires specialized tools designed specifically for mixed metal manipulation. Your ability to develop unique designs will depend largely on the specialized pattern-making tools you use to work with the metals.

Rolling mills play an essential role in achieving uniform thickness while enhancing the visibility of your layered patterns.

- Heat-resistant clamps and jigs hold your layered metals securely during fusion, ensuring precision in pattern formation.

- Custom chisels, files, and carving tools allow you to manipulate the metal surfaces with greater control.

- Punches, dies, and texture plates help you create specific shapes and imprint unique surface patterns.

These tools enable you to develop complex motifs like raindrop or ladder designs, transforming ordinary metals into extraordinary works of art.

Heating Equipment Essentials

While mastering the art of Mokume Gane requires skill and patience, your success ultimately depends on having the right heating equipment to properly fuse metal layers.

You’ll need either a propane torch or an electric kiln capable of reaching precise high temperatures that fuse without completely melting the metals.

Don’t overlook the importance of a quality soldering block or heat-resistant surface to safely conduct heat and protect your workspace.

Always pair your heating equipment with proper ventilation and safety gear like goggles and heat-resistant gloves to protect against fumes and burns.

Complete your setup with high-temperature tongs or tweezers for precise metal handling during the pattern development process, and a rolling mill to thin and stretch your fused layers into intricate designs.

Etching and Surface Treatment Methods

After mastering the basic lamination techniques, artisans can elevate their Mokume Gane pieces through etching and various surface treatments.

You’ll create depth and visual interest by applying resist to specific areas before introducing acid solutions that selectively remove metal layers. Different chemical solutions produce distinct effects, from subtle texture variations to dramatic contrasts between metals.

Surface treatments further enhance your work:

- Patination techniques alter colors and finishes, intensifying the visual contrast between layered metals

- Sandblasting and polishing create varied textures that highlight the intricate patterns of your design

- Chemical treatments reveal unique characteristics of each metal in your laminate

Always prioritize safety when etching—wear protective gloves and guarantee proper ventilation, as the chemicals used can be hazardous to your health.

Finishing Techniques for Mokume Gane Jewelry

The true character of Mokume Gane emerges during the finishing stage, where your meticulous lamination work transforms into wearable art.

You’ll employ several finishing techniques to enhance the surface texture and accentuate the distinctive layered patterns.

Begin with careful sanding, followed by polishing and buffing to reveal the intricate metal patterns. You can apply patina to create contrast between different metal layers, adding depth and visual interest. Oxidation treatments darken silver and copper elements, dramatically highlighting your design’s complexity.

Choose from various final finishes—matte, satin, or high-gloss—to customize your Mokume Gane jewelry’s aesthetic appeal.

Don’t forget to properly seal the piece to prevent tarnishing and preserve the beauty of your multilayered creation, ensuring your jewelry maintains its distinctive character for years to come.

Contemporary Applications in Modern Jewelry

Today’s jewelry designers have embraced mixed metal Mokume Gane as a cornerstone of innovative adornment, transforming this ancient Japanese technique into striking contemporary pieces.

You’ll find this versatile method applied across various jewelry types, where the fusion of gold, silver, copper, and bronze creates one-of-a-kind patterns that can’t be replicated.

- Personalized wedding bands featuring mixed metal Mokume Gane that tell a unique story through organic patterns resembling wood grain or flowing water

- Statement pendants that showcase the dramatic color contrasts achievable when different metals are layered and manipulated

- Everyday earrings that bridge high fashion with wearable art, appealing to collectors and casual jewelry enthusiasts alike

These distinctive pieces represent the perfect marriage between traditional craftsmanship and modern design sensibilities, making mixed metal Mokume Gane increasingly sought-after in today’s jewelry market.

Troubleshooting Common Mokume Gane Challenges

Despite its enchanting beauty, mixed metal Mokume Gane presents several technical hurdles that can challenge even experienced metalsmiths.

When working with this traditional Japanese technique, you’ll need to select metals with compatible melting points to achieve proper fusion. Silver and other precious metals must bond completely to prevent separation during heating.

To combat oxidation, always apply flux and maintain a clean workspace.

The unique blend of layers must be clamped securely before heating to guarantee consistent patterns develop during forging. If your design isn’t emerging as expected, adjust your forging pressure—too much or too little affects pattern visibility.

The Mokume Gane technique offers incredible artistic possibilities, but requires attention to texturing details.

When carving, use sharp tools appropriate for your intended design to achieve that distinctive layered appearance.

Advanced Pattern Manipulation Techniques

Five key techniques elevate Mokume Gane from simple layering to extraordinary artistry. By twisting, carving, and forging metal layers, you’ll create wood grain metal patterns that mimic natural forms.

Experimenting with varying thicknesses adds remarkable depth to your work, while punching and drilling techniques introduce raindrop or lace effects for dimensional complexity.

The mastery of heat and pressure during fusion dramatically impacts your pattern clarity. You’ll find that contrasting metals like copper and silver create stunning visual tension when properly manipulated.

- Try adjusting temperature and compression to reveal unique pattern variations

- Combine thin and thick metal sheets for enhanced visual depth

- Experiment with strategic punching to create organic, flowing patterns reminiscent of natural wood grain

Your finished pieces will showcase one-of-a-kind patterns impossible to replicate exactly.

Incorporating Stones and Other Elements

While Mokume Gane patterns create striking visual interest on their own, incorporating gemstones and other elements can dramatically elevate your work to new artistic heights.

Mixed metal Mokume Gane offers the perfect canvas for stone integration, allowing you to enhance the aesthetic value of each piece through thoughtful placement and setting techniques.

You’ll find multiple setting options available—prongs, bezels, and flush settings—each offering distinct visual impacts while securing your stones.

Whether you prefer arranging multiple small gems or showcasing a single statement stone, customization possibilities are endless.

Consider collaborating with clients during the design process to guarantee stone selection complements your metal patterns and colors.

For a truly meaningful creation, explore custom stone sourcing to incorporate personal gemstones that add sentimental significance to your Mokume Gane jewelry pieces.

Preserving and Caring for Mokume Gane Pieces

Because each Mokume Gane piece represents countless hours of meticulous craftsmanship, proper maintenance is essential to preserve its unique patterning and structural integrity.

The artistry of Mokume Gane demands respectful care to honor both its exquisite patterns and the artisan’s devoted craftsmanship.

The layers of different metals in your Mokume Gane jewelry require gentle care to maintain their distinctive appearance.

Keep your pieces looking their best by cleaning them regularly with a soft, lint-free cloth to remove oils and dirt without scratching the delicate surface patterns.

Store your Mokume Gane in a fabric pouch or lined jewelry box, away from harsh chemicals and extreme temperature fluctuations.

- Avoid contact with household cleaners, perfumes, and lotions that may damage the metal layers

- Remove your Mokume Gane jewelry before swimming or bathing

- Consider professional refinishing if oxidized finishes begin to wear away with time

Frequently Asked Questions

What Metals Are Used in Mokume Gane?

You’ll find mokume gane uses precious metals like yellow, red, and white gold, silver, and palladium. It also incorporates fine silver, 14kt gold, copper, and Art Clay metals for their compatible melting points.

Why Is Mokume Gane so Expensive?

Mokume gane’s expense comes from the precious metals you’re getting (gold, silver, copper), combined with the labor-intensive craftsmanship. You’re paying for skilled artisans, rare materials, and unique patterns that can’t be mass-produced.

What Is the Difference Between Damascus and Mokume Gane?

You’ll find Damascus is made from iron/steel alloys for functional blades, while Mokume Gane uses precious metals like gold and silver for decorative items. Damascus emphasizes strength; Mokume Gane focuses on aesthetic beauty.

What Is the Mokume Gane Used For?

You’ll find mokume gane used primarily in jewelry making, where it creates unique rings, pendants, and earrings. It’s also popular in knife handles, high-end accessories, and decorative art pieces requiring intricate metal patterns.

In Summary

As you explore mixed metal mokume gane, you’re connecting with a tradition dating back centuries while creating something uniquely yours. You’ll face challenges, but the distinctive patterns and depths you’ll achieve are worth the effort. Whether you’re making jewelry or decorative objects, your mokume pieces will showcase your skill and patience while honoring this remarkable metalworking art form.

Leave a Reply