You’ll make sterling silver harder through physical manipulation techniques like hammering, drawing, and rolling that deform its crystalline structure at the atomic level. These processes create smaller, denser atomic arrangements and increase dislocation density within the 92.5% silver composition. Hammering applies compressive forces, while drawing through progressively smaller holes compresses the metal and enhances tensile strength. Tumbling with steel shot provides controlled surface hardening, and advanced alloys offer superior mechanical properties for your specific applications.

Understanding Work Hardening in Sterling Silver

When you physically deform sterling silver through hammering, bending, or drawing, you’re triggering a fundamental process called work hardening that transforms the metal’s internal structure.

Physical deformation of sterling silver through hammering and bending triggers work hardening, fundamentally transforming the metal’s internal crystalline structure.

This mechanical deformation distorts the crystal lattice, creating smaller atomic arrangements that markedly increase the metal’s hardness and durability.

As you continue to work harden sterling silver through repeated manipulation, you’ll notice the metal becomes progressively stronger but less flexible.

The standard 92.5% silver composition responds particularly well to this process, developing enhanced mechanical properties compared to softer alloys.

However, you must balance work hardening with frequent annealing sessions.

Without proper heat treatment, the increasingly hardened metal becomes brittle and prone to cracking, limiting your ability to continue shaping and forming the piece effectively.

Physical Manipulation Techniques That Increase Hardness

You can greatly increase sterling silver’s hardness through several hands-on techniques that physically alter the metal’s structure.

Hammering and forging create compressive forces that rearrange the crystal lattice, while drawing the silver through progressively smaller plates compresses the material into denser atomic arrangements.

Tumbling with steel shot provides controlled impact that work-hardens the surface through countless micro-collisions.

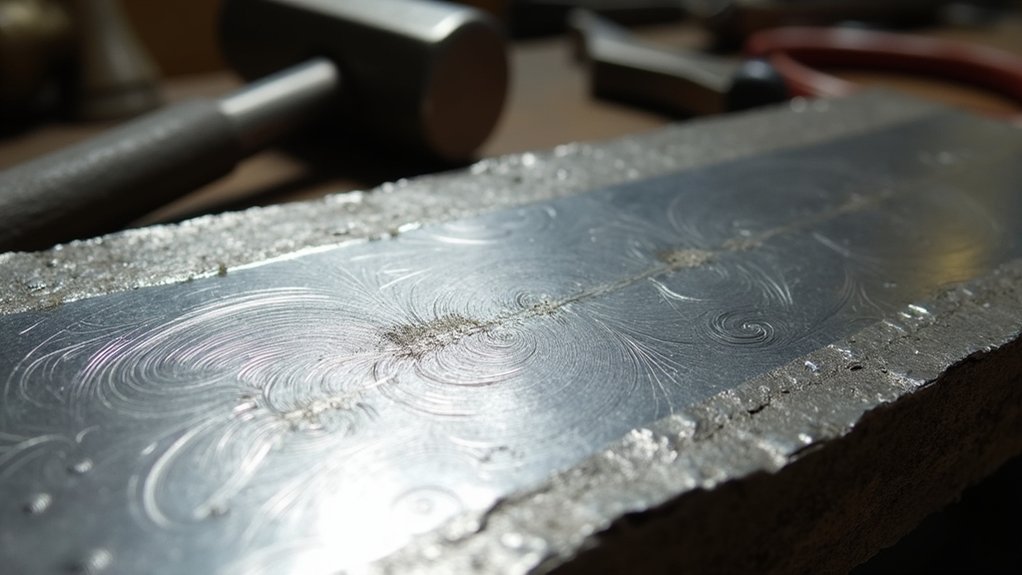

Hammering and Forging Effects

Although sterling silver starts as a relatively soft metal, hammering transforms its internal structure by compressing the crystal lattice and creating dislocations that greatly increase hardness through work-hardening. When you forge silver through repeated hammering, you’re realigning atoms and strain-hardening the material. Each strike changes the metal’s molecular arrangement, building durability progressively.

| Technique | Hardness Level | Applications |

|---|---|---|

| Light hammering | Moderate increase | Decorative textures |

| Heavy forging | Significant increase | Structural components |

| Multiple passes | Maximum hardening | High-wear jewelry |

The intensity and duration of your hammering directly affect the final hardness. You’ll notice substantial changes after multiple sessions, but remember that proper annealing between work-hardening phases prevents dangerous brittleness. This enhanced durability makes your finished pieces more resistant to daily wear and deformation.

Drawing Through Plates

Drawing sterling silver through progressively smaller holes in draw plates creates one of the most effective methods for systematically hardening the metal. When you pull the wire through each successive plate, you’re compressing and deforming the crystal lattice structure, creating smaller atomic arrangements that increase hardness markedly.

This drawing process reduces the cross-sectional area while elongating the silver, which enhances its tensile strength. The mechanical deformation increases dislocation density within the metal’s structure, resulting in work-hardening that makes your silver considerably less pliable.

You’ll need to anneal the sterling silver periodically during drawing to prevent excessive brittleness. Without proper annealing, the metal becomes too hard to work with effectively, potentially cracking under continued stress.

Tumbling With Steel Shot

Rotating stainless steel shot against your sterling silver pieces in a tumbler creates controlled surface compression that greatly increases hardness through repeated impact.

You’ll need to add water and burnishing compound to maximize the polishing and hardening effects during the tumbling process. After approximately thirty minutes, your jewelry emerges not only shinier but considerably harder due to the peening action of the steel shot against the metal surface.

Your tumbler won’t rust with repeated use, making it a reliable long-term investment for consistent hardening results.

However, you must carefully inspect each piece after tumbling to verify that delicate closures and intricate design elements haven’t been damaged. This technique effectively combines hardening with finishing in one efficient process.

The Science Behind Metal Structure Changes

When you work sterling silver through hammering, bending, or drawing, you’re fundamentally altering its crystal lattice structure at the atomic level. This process, known as work-hardening, creates dislocations within the metal’s atomic arrangement. These dislocations act as barriers that impede atom movement, directly increasing the material’s hardness and strength.

Sterling silver’s composition of 92.5% silver and 7.5% copper makes it particularly responsive to these structural changes. Each time you bend or manipulate the wire, you’re creating smaller atomic arrangements that resist deformation. The more you work the metal, the more dislocations accumulate, progressively hardening the material.

However, excessive work-hardening without periodic annealing can make your silver brittle, requiring careful balance between hardness and workability.

Hammering and Forging Effects on Silver

When you hammer sterling silver, you’re fundamentally altering its atomic structure through lattice distortion.

Each strike compresses the metal’s crystal arrangement, creating smaller, more tightly packed formations that greatly increase hardness.

This work-hardening process transforms your silver from a soft, malleable material into something significantly stronger and more durable.

Lattice Structure Distortion

How does hammering transform sterling silver’s molecular structure? When you hammer and forge sterling silver, you’re creating lattice structure distortion that fundamentally changes how atoms arrange themselves within the metal.

This mechanical manipulation forces atoms into tighter, more compressed positions, disrupting their natural crystalline formation.

The distortion process creates several key changes:

- Atoms pack more densely together, reducing spaces between them

- Crystal grains become smaller and more numerous throughout the metal

- The 7.5% copper content creates additional disruption points in the silver matrix

- Atomic planes shift and slip, creating internal stress patterns

- Overall flexibility decreases as resistance to deformation increases

This lattice structure distortion directly correlates with increased hardness.

You’ll notice your sterling silver becomes progressively stiffer and stronger as you continue working it through repeated hammering sessions.

Work-Hardening Through Impact

Work-hardening through impact amplifies the lattice distortion effects you’ve just learned about, transforming sterling silver’s mechanical properties through controlled force application.

When you hammer or forge sterling silver, you’re creating systematic deformation that increases hardness proportionally to the applied force. Each strike displaces atoms within the crystal structure, creating barriers that resist further deformation.

You can progress silver from dead soft to half hard or spring hard through repeated hammering. This work-hardening process strengthens your jewelry pieces, making them more durable and resistant to everyday stress.

However, excessive impact without annealing leads to brittleness and potential cracking. The key lies in controlling your hammer strikes and monitoring hardness levels to achieve ideal strength while maintaining workability for continued shaping and design modifications.

Drawing and Rolling Methods for Hardening

As you draw sterling silver through a draw plate, you’re compressing the metal and creating a denser atomic structure that increases hardness while the material elongates.

Rolling mills achieve similar results by reducing thickness while introducing strain that hardens the material.

Both techniques utilize work-hardening, where mechanical deformation creates crystal lattice dislocations that increase strength and reduce flexibility.

The hardness you’ll achieve depends directly on your reduction amount—greater reductions produce greater hardness.

Key considerations for drawing and rolling:

- Monitor reduction percentages to control hardness levels

- Anneal periodically to prevent brittleness and cracking

- Expect decreased flexibility as hardness increases

- Use consistent pressure for uniform results

- Plan your sequence to minimize material waste

Remember that continuous deformation without annealing can cause cracks, so balance your hardening goals with workability requirements.

Heat Treatment and Precipitation Hardening

While mechanical work-hardening offers one path to increased strength, heat treatment provides an alternative approach that harnesses precipitation hardening to enhance sterling silver’s properties.

Heat treatment unlocks sterling silver’s hidden potential through controlled precipitation hardening, offering jewelers an alternative to traditional mechanical strengthening methods.

You can heat harden sterling silver by heating it to 1382°F (750°C) for 30 minutes, then allowing it to cool slowly. During cooling, fine particles precipitate within the metal’s matrix, increasing hardness and strength considerably.

You’ll need a kiln or reliable oven that maintains consistent high temperatures, preferably in a non-oxidizing atmosphere to prevent firescale formation.

Standard sterling silver (92.5% silver, 7.5% copper) responds excellently to this process, unlike soft deoxidized alloys.

Digital pyrometers and controllers guarantee temperature stability, improving your success rate and achieving ideal hardening results.

Tumbling With Stainless Steel Shot

Beyond traditional heat treatment methods, tumbling with stainless steel shot offers you a mechanical approach that simultaneously hardens and polishes your sterling silver pieces.

This process creates compressive stress on the surface, greatly enhancing durability while delivering a brilliant finish.

Here’s what makes tumbling with stainless steel shot so effective:

- Non-corrosive properties – Stainless steel shot won’t rust or contaminate your silver

- Dual functionality – You’ll achieve both hardening and polishing in one process

- Quick results – Noticeable hardness improvements occur in just 30 minutes

- Consistent finish – The shot creates uniform surface compression across all pieces

- Simple setup – Just add water and soap or burnishing compound to your tumbler

This mechanical hardening method has become a favorite among jewelers for its reliability and efficiency.

Gauge Selection and Hardness Levels

When selecting sterling silver for your projects, you’ll need to understand how gauge thickness and hardness levels work together to determine your material’s performance.

Higher gauge numbers indicate thinner sheets, while lower numbers mean thicker material. For items like rings and bracelets that endure daily wear, choose 20 gauge or thicker for enhanced durability.

Sterling silver comes in four hardness levels: dead soft, quarter hard, half hard, and spring hard. Dead soft metal offers maximum workability and can be hardened through hammering.

Half hard and spring hard sheets work best for minimal forming tasks like laser engraving.

Your gauge selection directly affects appearance—thicker materials accept deeper textures for striking visuals, while thinner gauges create delicate looks.

Consider your project’s intended use when choosing both gauge and hardness.

Comparing Dead Soft Versus Half Hard Silver

Among the most critical decisions you’ll make as a silversmith is choosing between dead soft and half hard sterling silver, as each offers distinct advantages that directly impact your project’s success.

Dead soft silver provides maximum malleability for intricate designs and initial forming, while half hard offers enhanced strength and shape retention through existing work-hardening. Your choice depends on your specific application needs.

Consider these key differences:

- Malleability: Dead soft bends easily for complex shapes; half hard resists deformation

- Spring back: Half hard maintains form after bending; dead soft may lose shape

- Work-hardening: Dead soft hardens through manipulation; half hard starts partially hardened

- Applications: Half hard suits rings and bracelets; dead soft works for textured pieces

- Durability: Half hard withstands more wear in high-use items

Spring Back Properties in Worked Silver

The spring back properties you’ll encounter in worked silver directly impact how your pieces hold their shape and close securely. When you bend half-hard wire, the metal’s elasticity causes it to partially return to its original position, creating spring back. This phenomenon varies with wire gauge—thicker wires show less spring back than thinner ones, giving you more stability in finished work.

Sterling silver’s unique composition of 92.5% silver and 7.5% copper creates varied atomic arrangements that influence how the metal responds to manipulation. You’ll notice different spring back behaviors depending on how you bend or twist the material.

To manage spring back effectively, over-twist jump rings when closing them. This technique guarantees secure closures and maintains proper fit in chainmaille weaves without compromising structural integrity.

Continuum Sterling Silver Advanced Alloys

While traditional sterling silver serves most jewelry applications well, Continuum Sterling Silver represents a significant advancement in precious metal alloys.

You’ll find this innovative material contains over 95% precious metal content while delivering superior mechanical properties that outperform standard sterling silver.

When working with continuum sterling silver, you’ll discover these key advantages:

- Enhanced hardness: As-cast hardness reaches 97-117 HV, making it over one-third harder than regular sterling

- Superior strength: Yield strength of 17,000 psi and ultimate tensile strength of 35,000 psi

- Reversible hardness: Maintains springiness in flexible components without sacrificing durability

- Familiar processing: Cold working techniques mirror typical sterling silver methods

- Controlled reduction: Maximum 60% reduction with proper annealing protocols

This advanced alloy transforms your jewelry-making capabilities while preserving traditional working methods.

Optimizing Hardness for Different Jewelry Applications

Because different jewelry pieces face varying levels of stress and wear, you’ll need to match sterling silver’s hardness to each application’s specific demands.

For rings and bracelets that endure constant contact, you should use 20-gauge or thicker hard silver to resist deformation and maintain structural integrity over time.

When creating delicate earrings or pendants with minimal stress exposure, dead soft wire works best since it allows extensive shaping without cracking.

However, choose half-hard or spring hard silver wire for pieces requiring both durability and flexibility, like chain links or decorative elements that need to hold their shape while accommodating movement.

Consider your design’s complexity and expected wear patterns when selecting hardness levels to guarantee peak performance and longevity.

Frequently Asked Questions

How to Work Harden Sterling Silver?

You’ll work-harden sterling silver by hammering, bending, or rolling it to distort the crystal structure. Draw wire through plates, tumble with steel shot, or repeatedly flex the metal to increase hardness and strength.

Does Sweat Affect Sterling Silver?

Yes, your sweat affects sterling silver by accelerating tarnishing through moisture and salts that oxidize the copper content. You’ll notice dulling and potential skin irritation, but regular cleaning prevents damage.

How to Make Sterling Silver Stronger?

You’ll strengthen sterling silver by work-hardening through hammering, rolling, or drawing. Try precipitation hardening at 750°C for thirty minutes, or tumble with steel shot. Use half-hard wire for balanced strength and flexibility.

Can Fine Silver Be Work Hardened?

You can’t effectively work-harden fine silver because it lacks copper alloys that create the hardening effect. Unlike sterling silver, fine silver remains soft and malleable regardless of hammering, bending, or drawing techniques.

In Summary

You’ll achieve harder sterling silver through consistent physical manipulation of the metal’s crystalline structure. When you hammer, forge, roll, or draw your silver, you’re creating internal stress that increases hardness dramatically. You can control this process by choosing between dead soft and half hard starting materials, then applying the right techniques for your specific jewelry application. Master these work hardening methods and you’ll create stronger, more durable silver pieces.

Leave a Reply