Wax to CAD jewelry conversion transforms your hand-carved wax models into precise digital designs through 3D scanning technology and computer-aided design software. You’ll start with a detailed physical wax model, then use high-resolution scanners to capture every intricate detail for digital files. The scanned data gets imported into CAD software where you can refine designs, make instant modifications, and prepare models for 3D printing or CNC milling production methods that guarantee consistent quality and dimensional accuracy throughout manufacturing.

Understanding the Traditional Wax Carving Process in Jewelry Making

When you’re creating custom jewelry, the traditional wax carving process serves as the foundation for altering artistic vision into tangible reality.

Traditional wax carving transforms creative concepts into physical form, bridging the gap between imagination and crafted jewelry reality.

You’ll work with specially formulated harder wax designed for sculpting, manually shaping intricate designs that require hours to days of skilled labor. This hands-on approach allows you to create detailed patterns with complex geometry and organic forms that machine-based methods often can’t achieve.

What makes wax carving particularly valuable is your ability to modify designs even after initial completion. You can easily adjust wax models based on client feedback before casting begins.

Since approximately 90% of custom jewelry designs still use traditional carving techniques, understanding this process becomes essential when shifting to CAD models for modern production methods.

The Role of CAD Technology in Modern Jewelry Design

Computer-Aided Design (CAD) technology has revolutionized jewelry creation by transforming how you conceptualize, design, and manufacture pieces. CAD programs enable you to create precise 3D digital models that replace traditional wax models, offering unprecedented accuracy and flexibility. You can visualize your final piece before production, making quick revisions while minimizing material waste.

CAD Software bridges the gap between hand-carved wax carving techniques and modern manufacturing. While organic shapes remain challenging compared to traditional methods, you’ll find that geometric designs excel in digital environments.

CAD-CAM systems automate your manufacturing process, ensuring dimensional accuracy and consistent quality. You can still incorporate hand-finishing techniques for personal touches.

This jewelry design evolution streamlines workflows, reduces costs, and allows unlimited design iterations without physical material constraints.

Step-by-Step Process of Converting Wax Models to Digital Designs

Although traditional wax carving remains a cornerstone of jewelry making, you’ll need to follow a systematic approach to convert your physical wax models into precise digital designs.

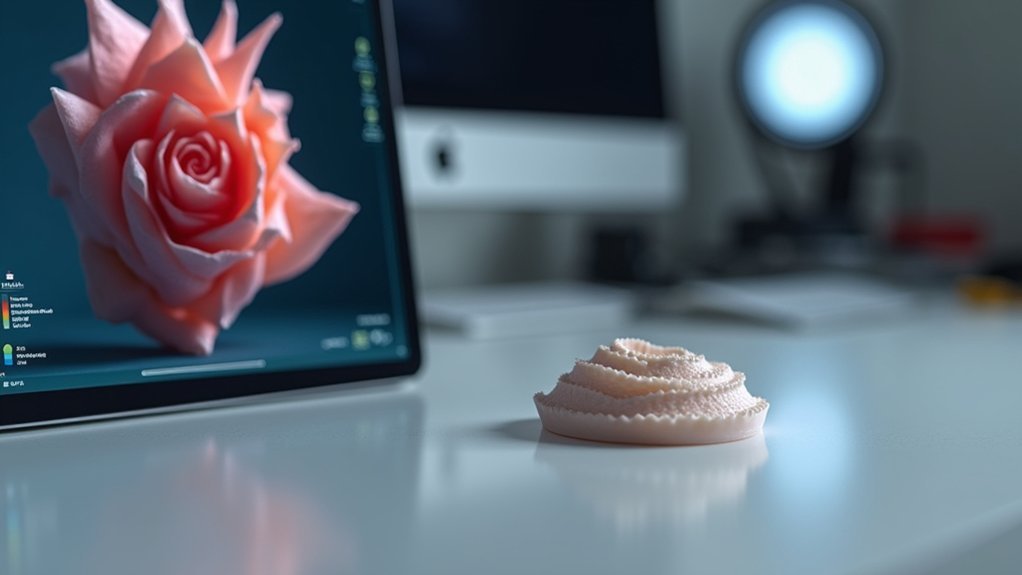

First, create a detailed jewelry wax model that serves as your physical reference. Next, use a high-resolution 3D scanner to capture every intricate detail, transforming your wax model into a digital CAD file format.

Import this scanned data into CAD software where you can refine and enhance the design. Once you’ve made necessary adjustments, prepare your digital model for production using CAD-CAM technology.

You can then proceed with 3D printing or CNC milling to create precise replicas, preserving original craftsmanship while enabling modifications.

Benefits and Advantages of Wax to CAD Conversion

Converting your wax models to CAD format delivers immediate advantages that revolutionize your jewelry production workflow.

Digital conversion of wax models instantly transforms your jewelry production, delivering revolutionary workflow improvements and unprecedented design precision.

You’ll experience dramatically reduced production times while achieving unprecedented precision in your designs.

Key Benefits of Wax to CAD Conversion:

- Enhanced Design Flexibility – Computer aided design allows instant modifications without recreating wax modeling from scratch, saving valuable time and materials.

- Superior Accuracy – CAD technology captures every level of detail from your original design, ensuring consistent quality across multiple pieces.

- Advanced Manufacturing Integration – Your converted designs can be used to create 3D printed models, streamlining the entire production process.

- Client Visualization – Generate realistic renderings for customer approval before casting, reducing revisions and ensuring satisfaction.

This shift transforms traditional jewelry design into a scalable, efficient digital workflow.

Choosing Between Hand Carving and Digital Design Methods

How do you decide between the time-honored tradition of hand carving and the precision of digital design methods? Your choice depends on project requirements and priorities.

Hand carved wax excels when you’re creating custom-made jewelry requiring intricate designs with organic, artisanal qualities. This traditional approach gives you tactile control and easy post-completion modifications, though it demands significant time investment.

CAD modeling offers superior efficiency for jewelry design, reducing material waste while enabling complex 3D models in hours rather than days. You’ll achieve precise, cost-effective production, but modifications become challenging once finalized.

Consider your timeline, budget, and desired aesthetic. If you’re prioritizing unique craftsmanship and aren’t constrained by time, choose hand carving. For quick turnarounds and complex geometric patterns, CAD modeling provides the ideal solution.

Frequently Asked Questions

What Does CAD Mean in Jewelry?

CAD means Computer-Aided Design in jewelry. You’ll use specialized software like Matrix or Rhino to create precise digital models, replacing traditional sketching methods. It’ll help you design complex pieces with greater accuracy and efficiency.

How Much Does a Jewelry CAD Cost?

You’ll spend between $109 and $8,000 for jewelry CAD software alone. Complete setups with milling machines and scanners cost $19,500 to $44,500, though leasing options can reduce your upfront investment considerably.

What Is Wax Setting in Jewellery?

You’ll create a detailed wax model that serves as your jewelry’s blueprint before casting. You can carve intricate designs into specialized hard wax, which becomes your mold for the final metal piece.

What Is Jewelers Wax?

You’ll find jewelers wax is a specialized carving material that’s harder than regular wax. You can sculpt intricate jewelry designs with it, then use those wax models for lost-wax casting into precious metals.

In Summary

You’ll find that wax to CAD conversion bridges traditional craftsmanship with modern technology, giving you the best of both worlds. You can preserve your hand-carved details while gaining digital precision and manufacturing flexibility. Whether you’re scaling production, making modifications, or archiving designs, this process lets you maintain artistic authenticity while embracing efficiency. You’re not choosing between old and new methods—you’re combining them for superior jewelry creation.

Leave a Reply